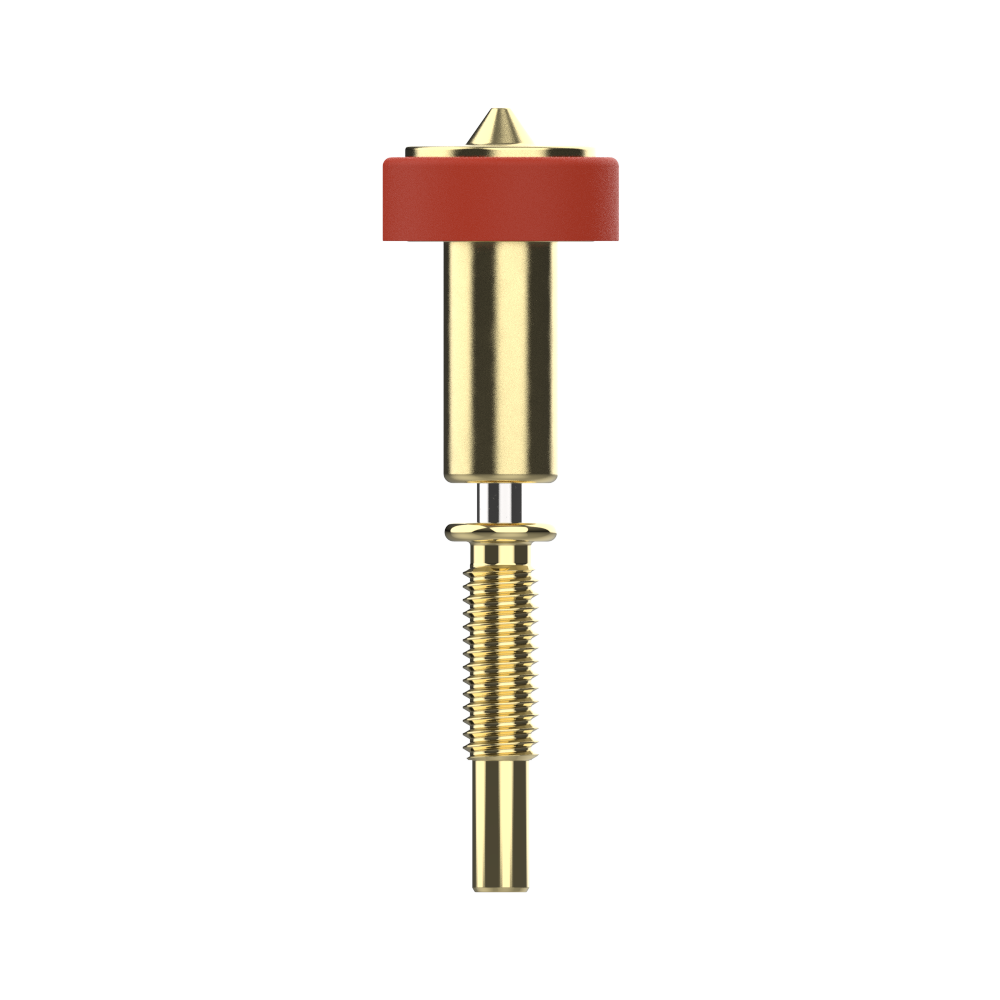

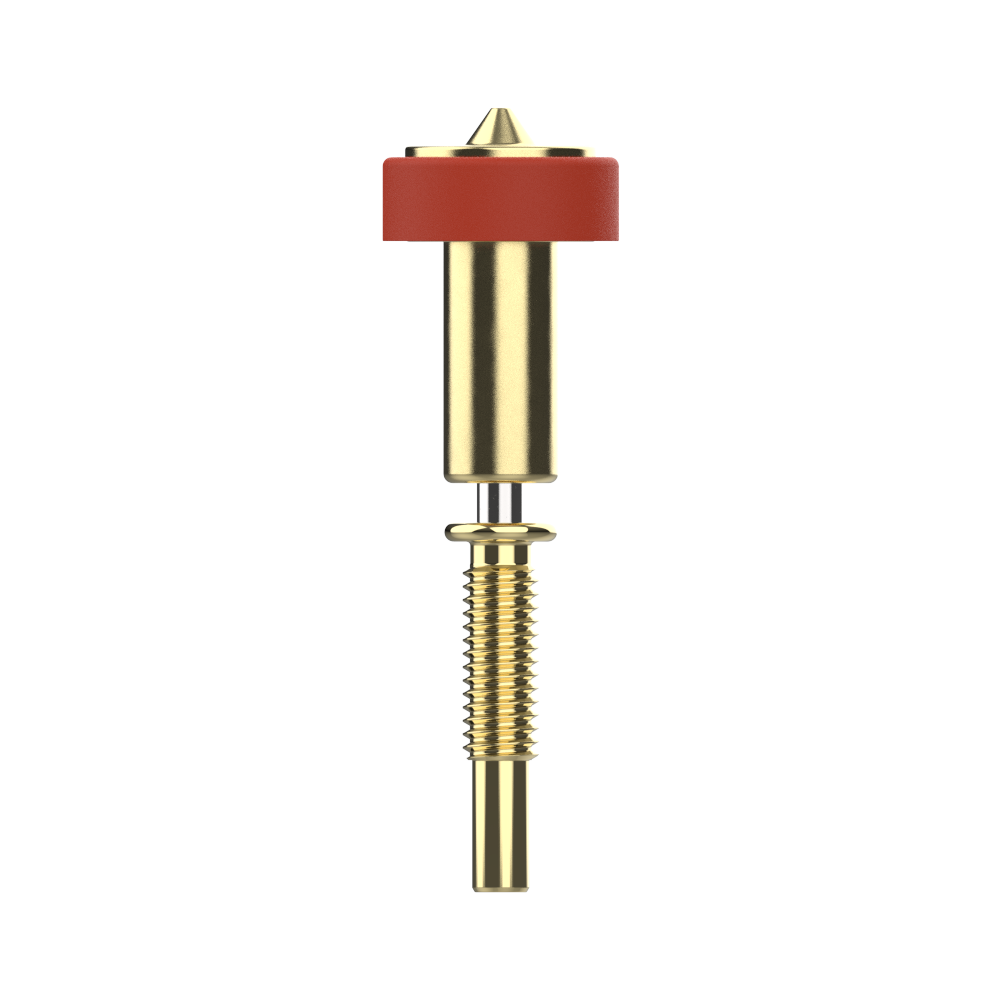

Revo Support: Brass Nozzle

Revo Support: High Flow Brass Nozzles

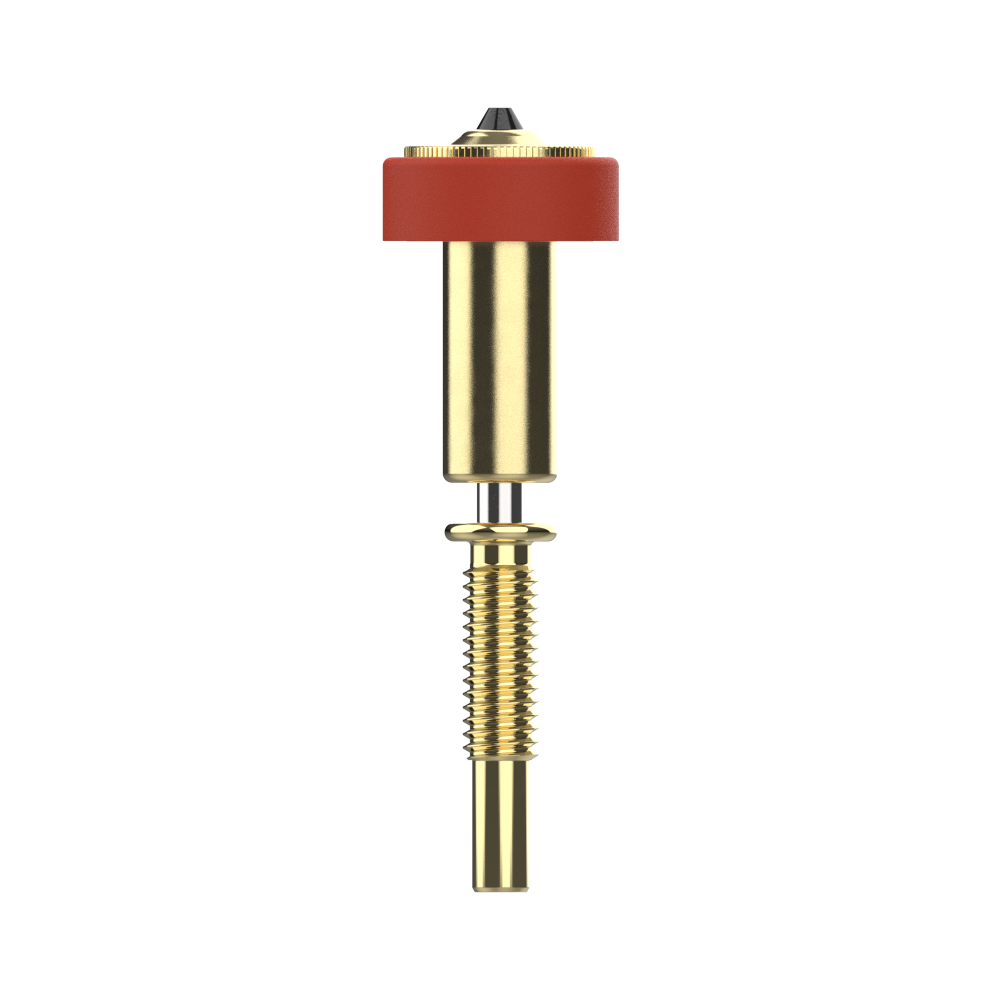

Revo Support: ObXidian Nozzles

Revo Support: High Flow ObXidian Nozzles

Revo Support: HT Nozzles

Revo Support: HTA Nozzles

Revo Support: High Flow HTA Nozzles

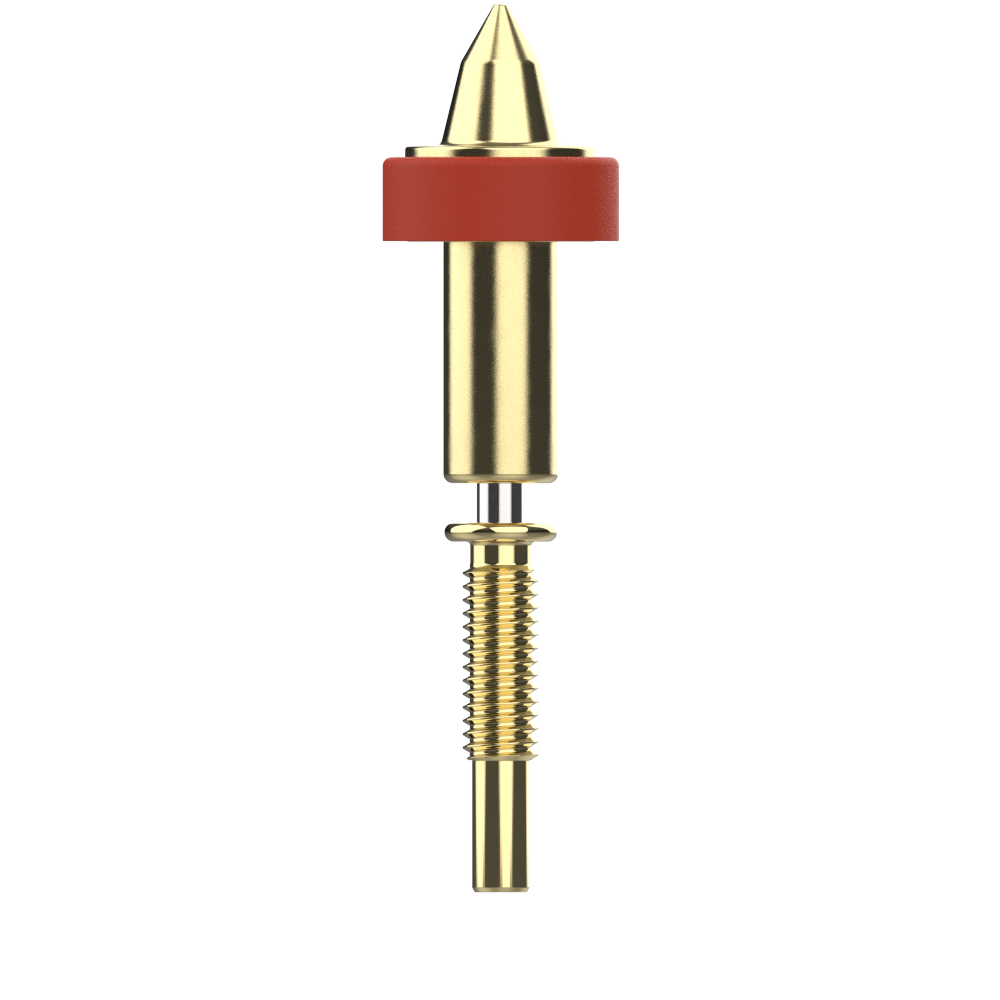

Revo Support: DiamondBack Nozzle

Revo Support: Non Planar Nozzles

Revo Support: High Flow ObXiDian 500 Nozzles