After the unfortunate sequence of events which led to Bearing-Gate and following some serious stress-testing by the engineering team here at E3D, we're happy to announce that all Titan Extruder products (including Titan Aero), are back in stock with a complete bearing and lid solution .

Briefly, here's a summary of what we've done:

1. Lids

Lids have now fully switched over to Tritan polymer. We've run really destructive tests on the new Tritan Titan lids (yes, it's a mouthful), baking them in the new bearing lubricant at 60°C for far longer than necessary, and we're happy with the results. No cracking; no deterioration.

Baked goods.

Baked goods.

2. Bearings

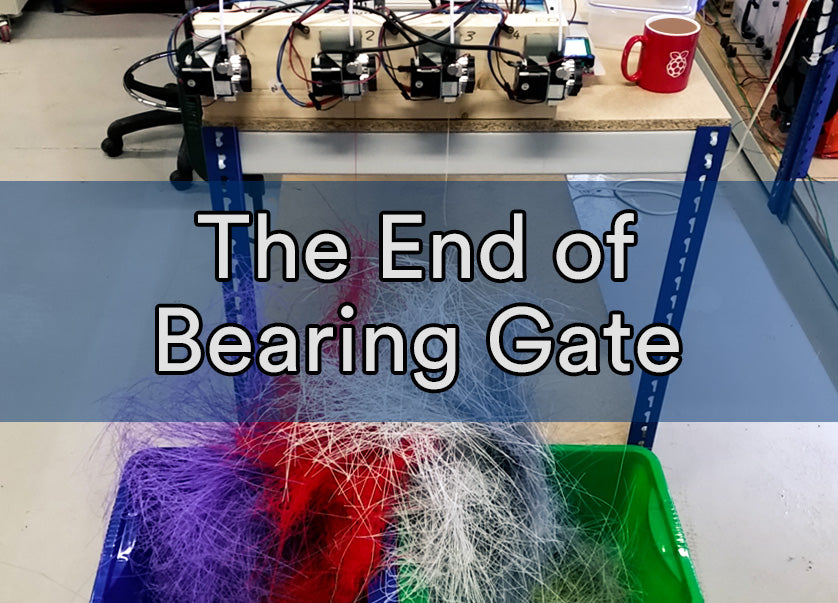

To test the proposed bearing lubricant we've been running an extrusion rig for hundred of hours: comparing old bearings to new by running the setups continuously. As we expected from customer reports, the old bearings did indeed fail within approximately 24 hours of continual and accelerated stress-testing. The new, improved bearings are still spinning away happily.

The bearings have had around 500 hours of testing under the most adverse conditions possible, running constant ram purges to apply maximum stress on the bearings, repeatedly. This approximates many more printing hours than just standard extrusion speeds.

The bearings have had around 500 hours of testing under the most adverse conditions possible, running constant ram purges to apply maximum stress on the bearings, repeatedly. This approximates many more printing hours than just standard extrusion speeds.

What to look out for

All Titan and Aero products from now on will ship with new Tritan lids (the only visible difference is a higher translucency) and with new, improved bearings. These bearings are visually indistinguishable from the faulty ones, but we've quarantined and removed all old bearings so that if you receive a Tritan lid you can be confident that the supplied bearings are correct.

Please ensure you continue to closely follow the assembly guidelines which are always kept up to date with any small changes.

Replacements

Please remember that if you've had a bearing failure in the meantime you can email us let us know.

If you're at all worried about your Titan lid, replacements are now available on our website.