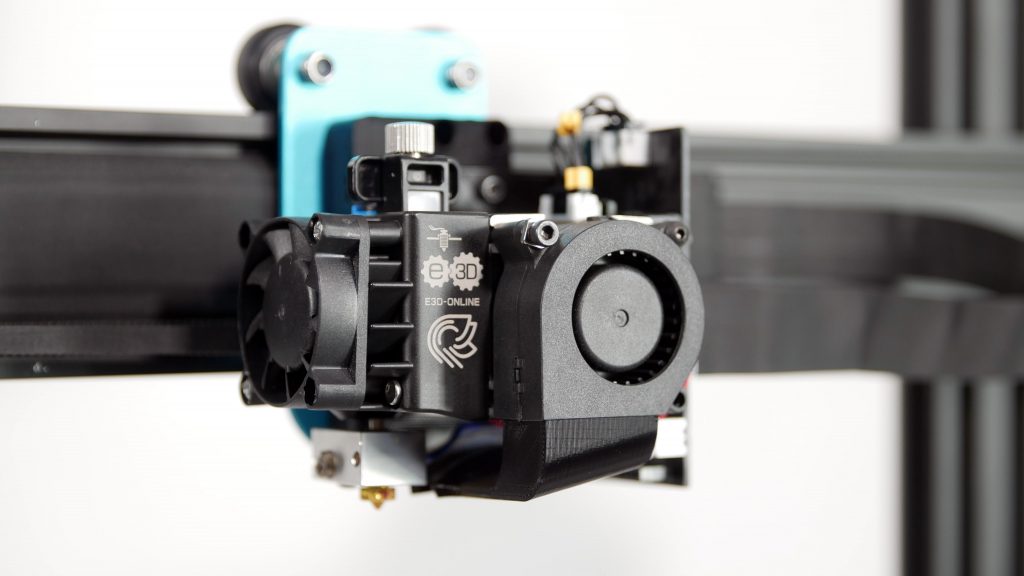

The vast majority of Hemera customers out there are enjoying the product, however, we have noticed and been dealing with, a number of issues that have cropped up since launch. We’d like to clarify a few things, apologise to those of you affected, and ensure our users have all the information they need and know what to do if they’re having issues.

As is sometimes the case with new products, the initial batch had some teething issues, but these issues are not widespread. If your Hemera is working fine, then there is no need to worry, but should you experience some issues we’ve put together the following info so you know how to get help.

There are more details below, however in summary:

- There have been some issues with misalignment of gears. If this has happened to you then contact customer support, we will replace a couple of components to rectify the issue.

This issue has now been fully resolved by our engineering team. - There have been some issues with cracking gears. If this has happened to you then contact customer support, we will replace the affected shaft to rectify the issue.

The issue has now been fully resolved by our engineering team. - There is a cosmetic defect with the heatsink pin - some Hemera heatsinks have a small cosmetic defect where swarf from pressing in the idler-pivot-pin protrudes through the front of the heatsink. This does not affect functionality.

We are still exploring solutions for this. - Some users have struggled with the T-Slots Breaking; using a screw of incorrect length will cause them to break.

We are clarifying our documentation and adding warning stickers over the T-Slots to minimise the chance of mistakes.

The first thing to say is that issues with cracking and misalignment are uncommon, and if your hemera is working fine then there is nothing to worry about.

Separately to the above issues, our supply chain for Hemera has been disrupted by COVID-19 which is why we are currently out of stock and unable to resupply resellers. With this in mind, we opted to bring back the small amount of stock that resellers had on hand to perform further checks on their holdings. By getting them back and testing those parts it means that when we restart shipping in the future we will have a ‘clean break’ where we are certain that all units going out have been subject to the same controls.

As with any E3D product issue in the past - we look after our customers, and stand behind our product. We have a history of looking after customers when, on the odd occasion, things haven't gone to plan. It’s a history we're proud of, and we don't plan to abandon that track record any time soon. If you are having an issue with the geartrain of your Hemera then get in touch - we'll sort you out pronto.

Misalignment of Gears

The root cause of this issue is that, in a small proportion of motors, the distance between the motor pinion-gear and the bearing pocket which defines the position of the large gear is too small. This occurred during the manufacture of the motor - and we are collaborating closely with our motor supplier in order to rectify this issue. We are confident that by helping them improve the process by which motor faceplates are machined the issue has been entirely eliminated.

If the distance between the large-gear and pinion-gear (Called out as D in the image) is too small then the gears are pressed together very firmly. The excessive contact force between the gears causes them to not run smoothly, and this causes the extruder to not be able to extrude effectively.

If your Hemera gears quickly develop a significant amount of orange rust-like dust on the large gear (within a few hours of printing) of the extruder this is related to gear spacing issue and you should contact support. This isn’t a defect with the ‘stainlessness’ of the steel or anything of that nature - it’s a mechanical issue that results in the removal of the passivated surface of the gears which ultimately causes an oxidative effect, with the mechanical issue solved the issue goes away.

If you are experiencing that your Hemera is not running smoothly, or the surface of your gear teeth is showing signs of wear or rust please get in touch with customer service.

Cracking Gears

The root cause of this issue was traced back to the heat-treatment of the gears, and was a particularly tricky defect to track down.

We previously believed that the cracking phenomenon was entirely due to small inconsistencies between the sizes of the components that are pressed together to form the gear assemblies. We believed that by fixing this we had eliminated the issue, and while it improved the situation dramatically there were still some reports of cracking coming back from customers.

Gears need to be extremely hard in order to resist wear and function correctly over time. However there is a fine balance between hardness and brittleness. External laboratory material testing revealed that in a small proportion of the gears the heat-treatment had resulted in gears that were too brittle and therefore cracked.

We have now established a heat-treatment regime that assures that the gears are tough as well as hard, and which has been verified by both external laboratory material testing and empirical testing in house.

You can check your Hemera gears using the method outlined in our video here.

We are now able to ensure with confidence that this will not occur in any more gears, and are able to provide known good replacement gears for anybody that has cracked gears.

If your Hemera is working well then there is no need to worry. Cracked gears will be obvious as they would slip on the shaft and your Hemera will not extrude.

Cosmetic Defect with Heatsink Pin

A common defect we are currently seeing is a burr where the idler-pivot-pin is pressed into the heatsink. On the front side of the heatsink, if the fan is removed there is a visible defect between the fins where the pin slightly protrudes through the heatsink.

The hole for the pin has been made a little small, and the end of the pin slightly too sharp. The act of press fitting the pin into the hole can cause a burr to be present at the end of the pin on the front of the heatsink.

We are working on a solution to this issue as this post is being edited, but do not yet have a definitive fix. This means we are not currently in a position to offer a remedy to this issue at this time.

This has no impact on the alignment of the pin, the idler, or the rest of the drive-chain whatsoever.

As mentioned above, a much smaller number of Hemeras are having some issues with the drive-train. This is totally unrelated to the pin-breakthrough. Functionality is completely unaffected by the burr/unclean-breakthrough.

There is no correlation or connection between the cosmetic issue, and issues with gear alignment/cracking (which is far far rarer).

T-Slots Breaking When Used With Incorrect Length Screw

Everyone who uses a workshop loves T-Slots. They are a very convenient way of mounting things, we were committed to making use of this and were excited about how they would be received. In general, this seems to have been a good call and a lot of our users love the T-Slots.

They do however have a flaw. When used with a screw that is too long, it will bottom out in the bottom of the pocket and put an extreme force on the nut. (It’s a 0.5mm pitch thread, so even a small torque is enough to generate a lot of force.) When this happens the T-Slot itself fails. This is not due to poor quality material, it is due to this mounting system being used incorrectly. Some have commented that the brittle failure mode of the T-Slots resembles the failure of cheap die-cast items, however we can assure you that the material is the same tried and tested material as LDO normally use with their motor faceplates.

It is worth pointing out that as long as the screw does not bottom out, you can tighten the screw up as much as you like (within reason!) because the T-Slot is experiencing an equal and opposite forces between the mounting surface and the nut.

Unfortunately this aspect of our design is less intuitive to use than we were expecting. With this now documented and covered with very visible stickered warnings we feel this should help users mount their Hemeras without issues.

In Conclusion

Thanks for reading this far! It’s been a hard tale to tell, one that we are not all that proud of, but one that we have learned a great deal from.

As E3D grow, the number of products that we have to get out the door has dramatically increased. We have learned a great deal from what would once up-upon-a-time have been minor issues, but today are very challenging. Our experience has given us insights that we look forward to building it into our next range of products.

We are satisfied that we have fully rectified the two issues discussed above, and as soon as our supply chain is back in full swing we are looking forward to having Hemera back on the shelves and in plentiful supply.

1 comment

Hello my gears its broken