Please note the E3D ToolChanger is now discontinued, story here.

We’ve been building a tool-changing 3D printer, and an incredible motion system to support it.

TL:DR: We’ve developed a tool-changing 3D printer, which might just be the coolest thing to hit 3D printing in a very long time. We’ve built it on what we think is one of the best motion systems ever put on a printer.

Note this blog post is about ToolChanger Version 1; read about how we updated the machine here

ToolChanger is out of beta and available to buy now!

We’re going to be doing a speech about it at Midwest RepRap Festival too, which should be being live-streamed and we hope to be taking questions from social media too.

So what we have here is a tool-changer and a motion-system. The two go hand in hand; the motion system is a fundamental part of what makes the tool-changer work, and the tool-changer adds immense value to the motion system.

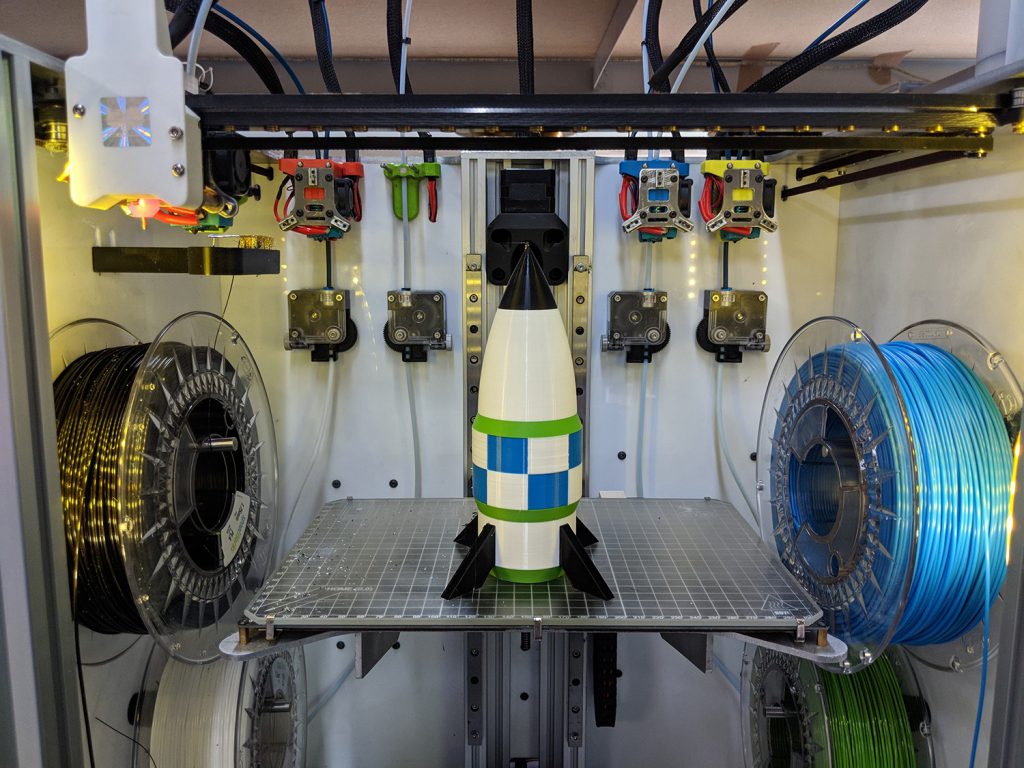

3 materials in one print

3 materials in one print

Why Tool-changing?

3D printing with multiple materials is undeniably cool and useful. Not only does it allow for attractive multi-coloured prints, but also (and we believe more importantly) for complex geometries with soluble support, and functional material combinations printed in a single part. Think carbon-fiber reinforced nylon, flexible materials, and soluble support all in a single part.

“Normal” multi-material printing, the status quo

Achieving reliable multiple-material printing is complicated. Historic approaches have included:

- Putting two (or more) nozzles on one moving carriage (as seen with the Chimera HotEnd or Ultimaker3 printer). The problem with this approach is that inactive nozzles tend to interfere with the print by oozing and knocking into the print. The nozzles and/or toggling mechanism also add weight to the carriage.

- Outputting more than one material through a single nozzle (as seen with the Cyclops HotEnd or Prusa MultiMaterial system). This approach requires lots of purging (wasting time and filament) to prevent filament cross-contamination, and even given perfect purging some materials remain incompatible. It also limits output to a single nozzle size in a given print.

- Mounting two carriages on the same machine (as seen with IDEX systems). This is the best so far, but is another method that limits the number of nozzles, as well as reducing print volume due to bulk and making one axis quite heavy.

Tool-changing overcomes all of the major downsides listed above:

- Inactive nozzles are stowed away, so there’s no ooze and no interference

- Only the weight of a single print-head is being moved at once, so it’s quick!

- Each material has its own dedicated nozzle, so there’s no cross-contamination and you can use the ideal extruder for each material or use-case

- Our machine is limited to four tool-heads due to volume constraints, but there’s no reason why more couldn’t be added. This means a potentially unlimited number of materials in one print if you used something like a tool-carousel in a machining centre.

It also makes some aspects of multi-material 3D printing quite easy in many ways, because you can, for example, calibrate all of your offsets in software (including Z!), and many of the usual multi-extrusion system issues just go away.

But there is one major downside: It’s the least explored method, and being able to pick up and put down tools both reliably and accurately is a significant engineering challenge that must be overcome for tool-changing to be viable.

We have overcome that challenge, with resounding success.

When we saw what Lulzbot were doing with their toolhead system last MRRF we were jealous. Their ideas were noble, and used novel systems like electro-permanent magnets. However, we wanted to take a different path.

A tool-changing system done properly is a BIG DEAL, opens huge future opportunities, and we’ve approached it very differently from LulzBot, and from what’s come before.

History

Of course we’re under no illusions that this is the first time that tool-changing has been tried. This project has provenance going all the way back to Adrian Bowyer’s work at Bath University. There have been many experiments since then too, including Ultimaker and Lulzbot mods, among others. There were some persistent problems though; the resultant machines consistently lacked a reliable, lightweight and precise tool capture mechanism.

Aside from this, most only offered a mere two toolheads. We didn’t want only two heads, we wanted four with the potential to go for even more. And we wanted a reliable precision coupling mechanism to get us there.

Aims:

Use dissimilar heads in one print.

We want to have one print-head perfect for flexible printing, and another for a hardened-steel Volcano. And yet another just for soluble support material, so there’s never a danger of filament cross-contamination. One of the things we’ve learned over the years at E3D is that physics doesn’t let us make a “perfect hotend” for all use cases, so we usually have to compromise. Not so with tool-changing. We can use exactly the right hotend for the right application.

No human interaction during printing

Because human labour is not how the future of manufacturing will be going down.

Use more than two print-heads in one print.

We don’t want be restricted to using just two heads. We want to have more than two tools, so we can have multi-material prints with dedicated support material.

Our entry into the OpenRC championship

Our entry into the OpenRC championship

A system that is extensible and futureproof.

We want to be ready for the future, to open the door for the easy addition of tools that are not just additive. We can’t yet be certain what those will be, but we want to contribute to finding out. Hybrid additive/subtractive is a huge potential application, where a subtractive cutter might trim a layer to perfect dimensions and surface finish halfway through a print. Pick and place heads could grab non-printed vitamins like bearings, threaded inserts or embedded electronics. Metrology and inspection could be integrated with measuring probes, lasers, or even vision sensors. Perhaps lasers or inkjet for high-detail part marking - the sky's the limit here.

Tool-changing isn’t just another way to print in multi-colour, it’s a fundamental shift in capability and lays the foundation for future advances. We’re looking for partners to work with on this project, and there is potential for an open standard to be developed and established.

How we did it:

A great deal of trial and error to start with. This is something that we’ve been thinking about and working on for a while, and we’ve tried a miscellany of different methods (in different combinations) without much success. In the interests of openness and learning, here are some of the failed systems we physically prototyped:

Failed Systems for Grabbing the heads:

Pneumatic sucker-grabber

Similar to the robot-arm suckers that pick up car panels in factories, this had great pickup force, and was lightweight as the pump was off the carriage. Unfortunately it was too loud to be viable, as well as too expensive to source good-quality pumps. There was also the danger that if the vacuum-sealing mechanism didn’t work perfectly then it would lose its grip entirely. Contamination, seal and wear were all things we struggled to fully resolve.

Electro-Magnets

These offer a good deal of force, and had the benefit of being potentially quite low-cost - we had the idea of repurposing door locking mechanisms to suit our needs. However they require a lot of power and generate heat to boot, and were also larger and heavier than we were willing to work with.

Electro-Permanent Magnets

We liked their grabbiness; they’re definitely very grabby and grippy, plus they don’t require lots of current and don’t generate heat. But they are expensive, tricky to source reliably and, again, too bulky and heavy.

Toggle locks and permanent magnets

Alluringly cheap, but had the bad habit of conflicting with precision locationing. They also require a space-consuming sideways movement (resulting in fewer tools per machine).

Failed Systems for locating the heads:

Tapers

As people who do a lot of machining these were our first thought (like machine tools). They’re proven to work and can handle very large forces and loads on the head. However they proved to be too heavy for our purposes, as well as being expensive to make. They also require a large seating force actuated with something like a drawbar, and if too much load is applied then considerable force is required to remove the taper from the holder.

Pins (and a lot of tolerancing)

This was a simple potential solution, but it was just not precise enough (not to mention fiddly!). It would have been possible to machine precision parts to a high degree of accuracy, but too expensive.

Full XYZ probing and software compensation

This is a very new and underdeveloped method which would have been prohibitively time consuming and expensive to fully develop.

But we got there in the end:

Successful System:

Kinematic Coupling

Very very precise. Stupidly precise. Seriously, we’re seeing precision better than 5um, this took a great deal of tuning, tweaking, and we had the advantage of E3D’s precision manufacturing capability. It’s not easy, but when you get it right, it really works. It offers reliable capture and self-align even with imperfect alignment in the order of a few mm. Excluding the precision ground coupling elements, it can even be implemented with low cost off the shelf parts.

.

.

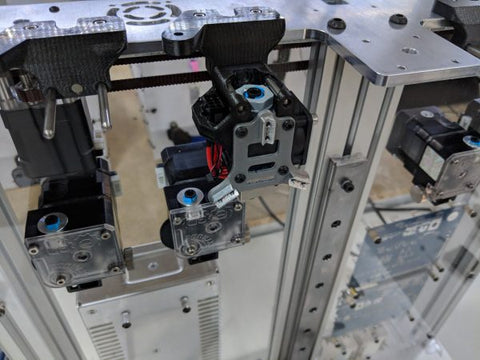

Lightweight servo actuator powered grabber

Small and lightweight, RC aircraft servos are highly developed optimised low weight actuators for low cost. They’re also easy to actuate and control from existing electronics.

Sprung Bayonet cam-lock

Cam-locks into the tool, applying a spring pre-load to the kinematic coupling. The servo rotates the cam-shaft through 3:1 gear reduction for torque, the bayonet fitting rotates, locks and cam-pulls into a slot in the tool head. It acts like a kind of hotend-suspension, providing a positive lock that makes it near-impossible for a tool to be dislodged due to impact. If the head gets knocked, it just snaps right back into place.

Locking mechanism

Locking mechanism

We did the prototype in DMLS, 3D printed in steel because it was a complex part geometry, and we gold plated it (for speed but also for bling). The production version can be mill-turned relatively inexpensively.

The full design

The full design

Permanent magnet tool dock

Once the printer is done with the tool it is returned to the dock where magnets retain tools that are not in use.

Motion System

Of course, if you’re going to do tool-changing, we believe that you should integrate it with an amazing motion system too.

We needed to eliminate variables, so with the the tool-changer being able to drop and pick tools with sub-5um repeatability it would be a total waste for this to go onto a substandard motion system. Aside from anything else, this is a research platform, so we felt that it was worth spending money to eliminate variables and have a rock solid foundation.

Structure

The entire XY motion system is mounted to a single plate of milled aluminium. This plate is exceptionally stiff, especially in the directions where forces act on it.

PLATE ON EXTRUSION

CoreXY: Fabtotum Style.

The fab-totum derivative of CoreXY is about as perfect as a belt driven XY system gets. It’s lightweight with no flying motors, all belt paths are all planar with no rubbing, and it produces only miniscule racking forces over a very short lever arm resulting in a tiny moment. With the Hiwin rails we’re using, this miniscule moment is a total non-issue.

We put our motors right in the back - just by the electronics - making wiring a dream. This should also help with Electromagnetic Interference (EMI). Most manufacturers that are making machines pay little heed to EMI, but it’s a very important part of modern consumer electronics and having a reliable machine that gives stable temperature readings.

In a CoreXY system of any sort you must have a moving cross-bar. The mass of our cross-bar, as the largest moving-mass in the XY system, would effectively define maximum print accelerations and speeds.

.

.

Our cross-bar is also long, spanning the full 300mm direction of the print bed. This might seem a strange choice for stiffness and moving mass, but this was intentional as we wanted the most space to mount tools on the back side of the machine. Hearkening back to BigBox, we also wanted to preserve the open-fronted machine. As a research platform it just makes things so much nicer to work on.

This long rail however does mean that we have to move more mass, so we went a little fancy and chose to use a machined carbon-fibre plate as the gantry bar. It’s incredibly stiff and strong. It’s also incredibly light, at a mere 120g. This gives us crazy-awesome acceleration and jerk rates, so we feel the money was well spent.

For the rails we used proper, genuine, Hiwin rails. It perhaps shouldn’t have shocked us how much better they are than the clones, but it did. They are SO much better, with exceptionally smooth motion and the level of rigidity from preload is incredible.

The Hiwin rails are bolted directly to the XY motion plate, as are the motors using stand-offs, resulting in a completely rigid XY system that is highly planar. Idler bearings for guiding the belt paths are mounted on rigid cantilever posts. All the belts run and track true without drift.

The rail running along the carbon gantry is also a genuine Hiwin rail, but a slimmer one to keep mass low.

For the belts we’re using the very best, genuine Gates GT belts and pulleys, which really reduces “ringing” artefacts in prints and ratchets up the accuracy.

Genuine belt porn

Genuine belt porn

Uprights

The plate is supported by precision-length extrusions on the corners and at the Z-Axis Backbone. These extrusions are end-tapped and have the top and base plates bolted to it, producing exceedingly stiff connections and enforcing orthogonality of the plate. The flatness of the aluminium tooling plate is very good indeed and makes a great substrate for mounting on motors and rails. The simplicity of the system makes it easy to manufacture and assemble, as well as being more than sufficiently rigid for any application, current or conceived.

Z-Axis: Like a Boss.

We’ve gone for one big, fat, super-stiff, pre-loaded linear rail; one very high quality integrated leadscrew motor with antibacklash nut; and a cantilever bed of exceptional rigidity. It provides the very best Z-layer stacking we know of and eliminates any risk of ‘seizing’ the Z-axis as with the BigBox. The integrated leadscrew motor is also mounted directly to the XY plate, enforcing orthogonality and eases assembly.

We used 2x thinner rails initially, but this was a pain to tram and was overconstrained. We also tried playing with ballscrews, however they didn’t make much sense in this application, taking up more space, weight, money and adding excessive resistance to motion due to pre-load.

The bent cantilever bed bracket is extremely stiff and does not have any resonance or flap that is often seen on some cantilever beds.

This image is of the bed loaded with around 4kg.

This image is of the bed loaded with around 4kg.

So now we have a Motion system, we need tools to put on it.

Tools we have so far:

-

Normal bowden v6, with Titan mounted on backpanel.

- Great lightweight all rounder.

- Adaptable to suit many materials through a range of nozzles, sensors and blocks.

A mounted V6 HotEnd.

A mounted V6 HotEnd.

-

Volcano Bowden v6.

- For faster, stronger work.

- Also adaptable with a range of nozzles.

A mounted Volcano.

A mounted Volcano.

- Flexible specific extruder based on v6+NEMA8 direct double drive

Tools we are developing

- A Titan Aero extruder.

- A better extruder for flexible filaments.

- A subtractive cutting head.

- A laser, perhaps for part marking or edge finishing

-

A Raspberry Pi Zero camera head, for in-process inspection

A Raspberry pi inspection rig.

Obviously different nozzle sizes including volcano can be derived from the above v6 and Volcano HotEnds.

To print flexibles we made the flexibles extruder, which is just a tiny NEMA8 on top of the hotend at present, but we’re making an even better one.

A flexibles build.

The tools have a magnet embedded in them, as does the dock at the back of the machine. This means that when the tool is dropped off by the printer it is held firmly in place.

Calibration

The tool configuration makes z leveling a dream, as the nozzles do not have to be levelled with each other; each one can have a separate offset. Entirely software defined. And super easy to calibrate with just the Mk1 eyeball and a pair of calipers. Thanks to the inspiration from nirfriedman on thingiverse- ours is derived from that concept, extended to four heads.

Calibration print along the Y axis.

Calibration print along the Y axis.

The test print takes just a minute or two to run, can immediately be assessed by eye to get calibration to within 50um in XY, and measuring with calipers gets you to within 10um on Z. It’s fast, it’s easy and we really like it.

Electronics and Driving it all

We wanted this thing to be an open platform for whatever electronics the user wanted to put on it. However, when it really came down to it, the only solution with enough extruder outputs and firmware that was truly scriptable and hackable was made by our great friends at Duet3D. The scriptable nature was so essential in allowing us to script tool changes and wipe scripts. There’s no reason why Marlin or Repetier couldn’t be made to do this too, but really, we found this to be the slickest easiest way. They are also amazing electronics with a 32bit ARM and Trinamic drivers that can do our motion system justice.

The rear wall with beautifully built-in electronics.

We did however opt for a BL Touch as bed levelling sensor in place of Duet’s IR endstop. We just have a bit of a mechanical fetish for getting true probed measurements.

BL Touch.

BL Touch.

Slicing

We’re using Simplify3D. It’s not ideal, as most of its logic is built around single or dual-extrusion printing. However, with the hackability of the Duet electronics scripting we do have a working solution. It’s an unwieldy process using 4 whole processes to print a single model but it still just about works.

Design for manufacture.

The whole structure is:

- 2x aluminium plates.

- 5x cut lengths of aluminium extrusion.

- 4x linear rails.

- 3x motors

- Some belt.

- Some screws and stand-offs.

While milling things out of tool plate isn’t cheap, it does make for a superbly accurate system and is worth it. The remaining items can be made at reasonable costs as they require very little complex machining. This allows us to spend money where it really matters, in the carbon cross-member, genuine Gates belts, and genuine Hiwin rails.

Design for assembly

We assembled the motion system of our second iteration of this machine in about seven minutes. Yes, seven minutes. Electronics and wiring will depend on which system you choose, and how fastidious about making the wires beautiful you are, but the motion system is elegant and simple to put together.

ToolChanger is available to buy now!