TL; DR: High Flow done differently. Six innovative new Nozzles, available to buy right now!

RapidChange Revo™ High Flow: Just a Nozzle swap away!

High-flow 3D printing is becoming more accessible than ever and thanks to our newest innovation, high-flow printing is just one nozzle swap away! We are thrilled to be releasing the RapidChange Revo High Flow Nozzles in six sizes from 0.4mm all the way up to 1.4mm, along with a 60W HeaterCore to maximise performance with high temperature materials such as Polycarbonate.

If you’re familiar with the V6 Ecosystem, you’ll know that we’ve done high-flow before, with our Volcano and later SuperVolcano systems. The way flow rate is increased in these systems is straightforward. By extending the meltzone, you increase the flow rate. It’s a simple and effective way to guarantee higher flow.

Revo was always going to be different. An ecosystem built on painless nozzle changes, going from a standard brass nozzle to a high-flow nozzle should be just as simple as going from a 0.4 to a 0.8mm. Herein lies a colossal engineering challenge. The kind that scares and excites our engineers in equal measure. Luckily for us, they rose to that challenge and delivered our innovative new Revo High Flow Nozzles.

Presenting Revo™ High Flow Nozzles

A 0.6 High Flow nozzle and a standard 0.6 Brass nozzle are virtually identical in the Revo Nozzle family. The only immediately apparent visual difference is a small ring circling the cone of the High Flow Nozzle. This ring is a by-product of how our High Flow Nozzles are manufactured, and it alludes to the hidden complexity of these new nozzles. If the nozzle has been used and you are looking for a way to distinguish your nozzles, remove the sock and look at the nozzle engraving. All Revo High Flow nozzles have HF engraved after the nozzle diameter.

Revo High Flow Nozzles are completely interchangeable with standard Brass or ObXidian Nozzles. You can go straight from a 0.15 to a 1.4mm in a matter of seconds. Just screw in a High Flow Nozzle for instantaneous flow rate gains.

The internal workings

The engineering inside these new High Flow Nozzles is fascinating and we want to tell you all about it.

The key to achieving this drop-in status is hidden on the inside of the nozzle in the form of some carefully optimised internal geometry. In order to increase the maximum flow rate at a given temperature you need to increase the surface area in contact with the molten filament. To achieve this, your design choices essentially boil down to two options:

Increase the length of the meltzone

Increase the surface area in contact with the filament

As we’ve already touched on, when designing our Volcano and SuperVolcano ecosystems, we elongated the meltzone. SuperVolcano’s chart topping flow rates demonstrates it’s an extremely effective way to improve throughput.

The problem with this approach is that your HotEnd assembly becomes considerably longer. Upgrading to high-flow systems like these will involve reworking your fan shroud and most likely your Z-endstop/auto leveling too. In some cases, the whole Toolhead may need redesigning and you may need to make changes in your firmware. This wasn’t such an issue in the earlier days of RepRap, but consumer 3D printers are steadily becoming less and less hackable.

So that leaves option 2, increasing the surface area within the meltzone.

Through our explorative R&D we’ve studied how geometry and thermal transfer combine to provide a flow rate. It’s one thing to work out what the perfect geometry would look like, but successfully manufacturing that geometry is another thing entirely. To achieve this we’re balancing several trade-offs; fluid dynamics, thermal transfer, manufacturability, and practicality of assembly.

Another key consideration is the required extrusion force. If you can get double the flow rate, but it takes eight times the extrusion force to achieve, that’s not such a good trade-off.

📷 Some geometry prototypes

When you 3D print, your HotEnd is converting a solid into a non-Newtonian, multi-phase fluid. If this sounds complicated, that’s because it is. Perhaps unsurprisingly, it’s difficult to accurately capture this process in computational simulations, which can make working out optimal geometry a real challenge. This resulted in A LOT of prototypes. We tested 28 different geometries to find the very best match for Revo, including the CHT geometry from Bondtech.

You can read all about how the Revo High Flow project has navigated Bondtech’s intellectual property in this blog by Clare.

The chosen geometry

📷 Part of a Revo High Flow Nozzle that has been sectioned to show the internals

📷 Part of a Revo High Flow Nozzle that has been sectioned to show the internals

📷 The geometry used for the High Flow portion of the Nozzle

This was the design we settled on; internally, we have been affectionately referring to it as the ‘spaceship’ insert. Fun fact: We had to consider the pointiness of the insert in the final design as we didn’t want any of our production team cutting themselves on its sharp point!

Prototype testing: How do we benchmark a flow rate?

This brings us on to our testing. We’re looking for the best flow rate but as mentioned earlier on, we’re also looking at the extrusion force required to achieve said flow rate.

Here’s a word from one of the Engineers behind this project, James:

“We use PLA for all our testing as it is one of the more difficult materials to obtain high flow rates with when compared to PETG or ASA. It’s also the most commonly used plastic in 3D printing. We use Prusament Jet Black PLA for all flow testing due to its dimensional accuracy and consistent and reproducible characteristics across batches. A key aspect of the development has been measuring the force required to extrude at increasing flow rates of each design, ensuring that results are repeatable and ensuring the nozzles are strong enough to avoid being damaged by cold extrusion.”

If you want more information on how we validate our flow rate data to ensure it is accurately portrayed, you should check out the testing procedure section of our Revo Nozzle Maximum flow rates documentation.

How well does it flow?

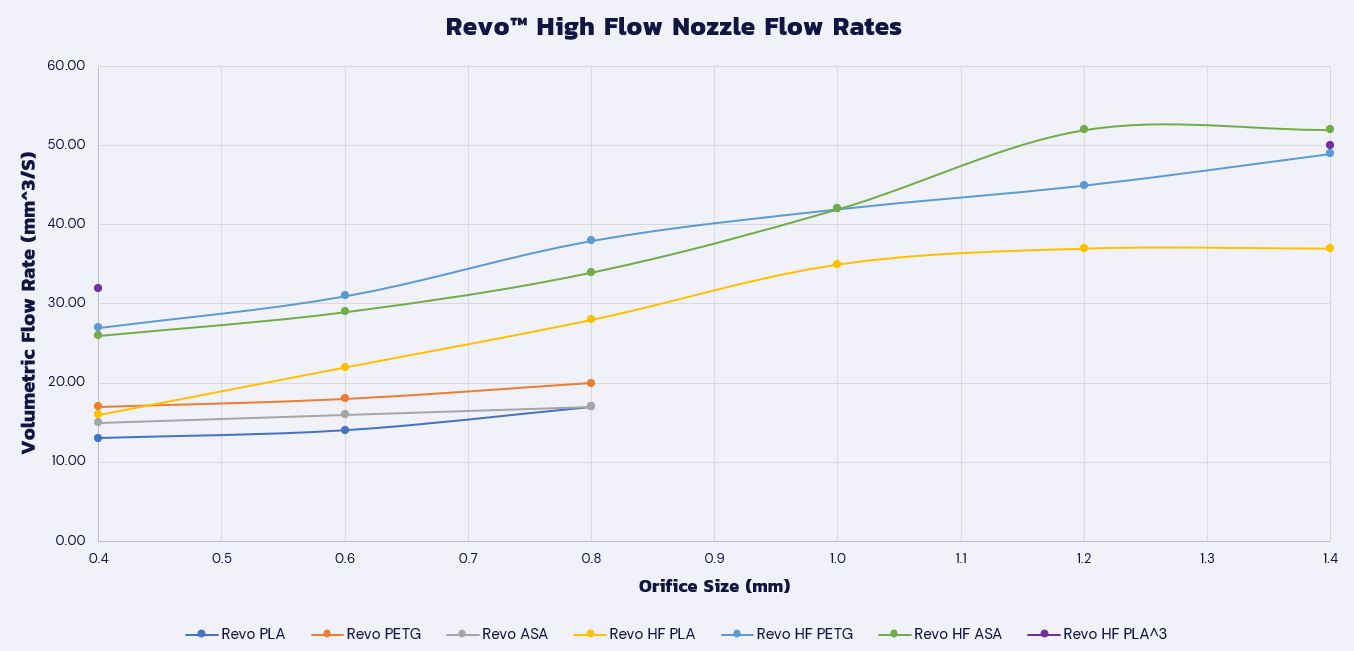

We’ve tried almost every HotEnd on the market and often find that their stated flow rate values are quite literally 'sliced' in half when subjected to our testing procedure. We believe it’s important to test a HotEnd under normal use case conditions to ensure values for flow rate aren’t artificially inflated. We also provide a flow rate value for each nozzle size as it has a huge effect on the maximum flow rate. You can find a full document of flow rates for different nozzle sizes and materials here.

📷 This graph shows a comparison between High Flow and Standard Brass Revo Nozzles when printing with PLA. The coloured dots relate to the sock colour of the nozzles.

A higher power, 60W HeaterCore

In some cases, when using higher temperature materials such as Polycarbonate, the standard 40W HeaterCore is not powerful enough to maintain the high temperature at a high flow rate.

The higher the flow rate the greater the requirement on the heater to maintain a stable temperature. This is because the filament traveling though the nozzle is absorbing and removing heat as it goes. We have developed a 60W HeaterCore to address this need.

📷 You may require a 60W HeaterCore if you wish to print Polycarbonate, ABS or Nylon using a 0.8mm Nozzle or larger.

We’ve got 0.4, 0.6, 0.8, 1.0, 1.2 and 1.4 Revo™ High Flow Nozzles available to buy right now! If you want more heating power, you can get a 60W HeaterCore. Check out our ever-expanding Revo line-up and make sure to follow our social channels for all the latest product releases.

We are thrilled to announce our newest addition Revo ObXidian High Flow Nozzles which will allow you to print abrasive materials faster! It is available to buy right now in 0.4, 0.8, 1.0, 1.2 and 1.4 mm nozzle diameters.

Buying outside the UK? Avoid additional charges and lead times by ordering from your local E3D Reseller. Looking for more technical info? Documentation for Revo High Flow Nozzles is available on the E3D Help Centre. If you have further questions, we’re available to chat on Discord or social media.

Frequently Asked Questions

If you've got questions about High Flow, you should find the answer here!

How did you get around the CHT patent?

You will notice an interesting label on the side of your Revo High Flow packaging: we’re delighted to say that E3D has reached a unique agreement with Bondtech, who have exclusive rights to the 3D Solex’s CHT patent, to license core heating technology for the Revo system.

So what does this mean?

Revo users have unrestricted access to our unique high flow system. We fully support 3D Solex and Bondtech’s IP ownership and rights over their Core Heating Technology. We stand with Bondtech against the cloners, the poor copies and the companies ‘trying their luck’ by ripping off CHT, or trying to circumvent their patent with quirks in design that they see as loopholes (spoiler: they’re not loopholes, and every product sold is taking income away from the CHT inventor, Carl Beck).

Does E3D have its own ‘patent pending’ high flow design?

Yes, we do. There are some unique features we are told are patentable, and an application is pending – at some point in the future the results of that will become clear and we expect to have patent coverage. The overlaps with the CHT solution mean we want to cover all the bases, and instead of launching a product regardless of Bondtech’s position, we approached Bondtech up front, and slowly built up a relationship and an agreement that works for both parties.

Will my Z-offset change when I install a Revo High Flow nozzle?

Revo Nozzles are all manufactured to the same length (within ±0.2mm) you will not need to reposition your Z-probe or re-level your bed. You may need to adjust your Z-offset to get a perfect first layer though.

Can you cold pull a Revo High Flow nozzle?

Yes, it is possible, however multiple cold pulls may be required to fully clean the nozzle.

Do I need to PID tune when I upgrade to the 60W HeaterCore?

Yes, as with any change to the hotend you should always run a PID tune. Bear in mind that some printer manufacturers use alternative thermal management systems such as the Prusa Mini. So check the advice from your printer manufacturer before attempting to PID tune.

How do I tell the difference between a standard nozzle and a high flow nozzle?

A high flow nozzle can be distinguished from a standard nozzle in two ways:

- The circle where the high flow geometry in inserted, located on the bottom of the nozzle (only visible when clean).

- When the sock is removed the nozzle diameter followed by ‘HF’ is engraved for easy identification.