Yet another failed 3D print? Ready to throw your budget 3D printer out the window?

Before you do, consider this: FFF 3D prints with crisp details, silky-smooth surfaces, and good dimensional accuracy all begin with a high-quality extrusion system. So, if you’re spending more time trying to make your 3D printer work than using it to 3D print things, maybe it’s time for an extrusion system upgrade.

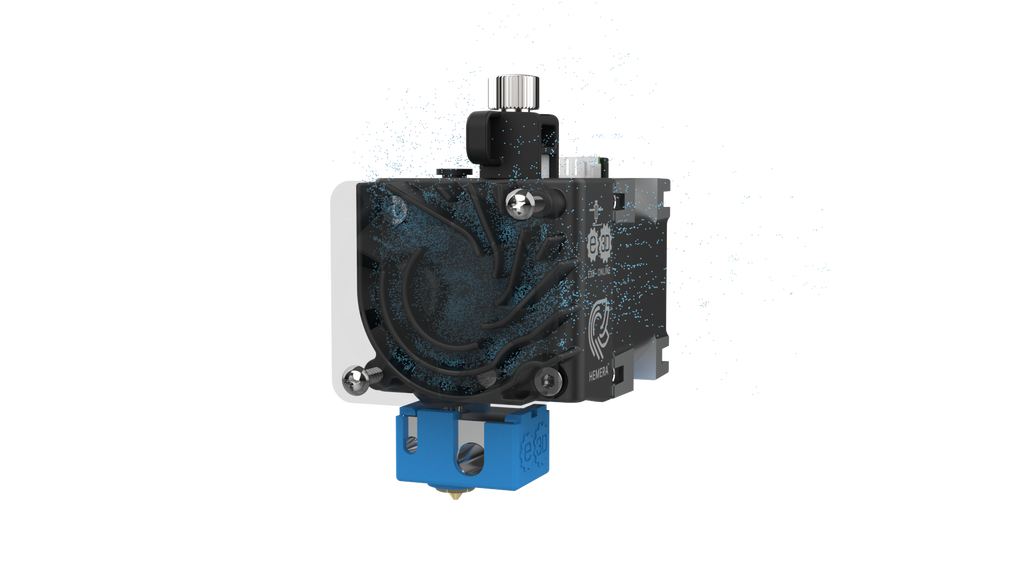

Meet Hemera: E3D’s top choice

You don’t need to pay premium prices for perfect 3D prints: Hemera will boost your 3D printer’s performance for less than £100. Overcome your 3D printing frustrations and start having fun again. Hemera makes 3D printing more accessible for beginners, and more powerful for advanced users, too.

⭐⭐⭐⭐⭐

Best upgrade!

Luis Alabaça on July 21, 2021

"This extruder is the best upgrade on my DIY 3D printer. It completely eliminates the extrusion problems I have with the other clones, and the price was accessible."

Hemera is the first combined extruder-HotEnd of its kind, drawing on almost 10 years of E3D extrusion system research and development. This precision engineered and manufactured extrusion system is compatible with all popular 1.75mm 3D printing materials, so you can 3D print with PLA, ABS, PETG, Nylon, carbon fibre filled materials, TPUs, and more.

Hemera is available in 12V or 24V to suit all popular machine types. Everything you need to start 3D printing is included in the box, and our detailed documentation guides you through mounting on popular 3D printers, including Prusa, Creality, LulzBot, and Artillery.

‘Buddha Pen Pot’ by Zane Rogers

3D printer: Prusa MK3S

Extrusion system: E3D Hemera

Material: Polyalchemy Silver Elixir PLA

3D print and photo by Filament Frenzy

⭐⭐⭐⭐⭐

Proper industry-quality extruder

Jakub K. on July 21, 2021

"I upgraded my CR-10 clone from a Chinesium Bowden to a Hemera, and damn! It's an amazing print improvement. Also the build quality and QC on it is amazing.

It might be more pricey than some Chinese clones but it's totally worth the money. The Hemera is built like a tank, and over the last few months I've been using it's never failed or had to be rebuilt."

Performance with the most challenging materials

Discover exciting new 3D printing materials that your stock extrusion system couldn’t handle. Hemera’s combined HotEnd and extruder design forms a compact, powerful direct drive system. A tightly constrained filament path means material can’t flex or bind as it’s pushed to the HotEnd, ensuring optimised, highly responsive extrusion control.

All popular 3D printing materials are compatible with Hemera out of the box, including PLA, ABS, PETG, and many types of flexible filaments. Even with the softest flexibles, you can maintain similar print speeds to PLA.

Stock Bowden extrusion systems tend to bind up when 3D printing flexibles, leading to print defects. Hemera’s tightly constrained filament path with fewer transitions means material can’t flex or bind as it’s pushed to the HotEnd

ITS FINISHED 😱

— Filament Frenzy ™ (@FilamentFrenzy) October 20, 2020

18 hours later full @Prusa3D MK3S build volume @DanielNoree benchy #PrusaSlicer 0.3mm default draft setting for PLA only change is 0.5mm retraction for my @E3DOnline hemera!

Watch until the end 🔨 pic.twitter.com/bfbnaVypRL

After it’s mounted on your 3D printer, Hemera is simple to use. All user-interactions happen at the top of the unit, including filament loading and idler tension. Just rotate the thumbscrew to adjust grip. Prefer a Bowden configuration? Hemera excels in this too. Just use our aftermarket Bowden adaptor (or ‘Bowdaptor’, as we like to call it), and you’re ready to go.

‘Form Fitting Insole’ by Gyrobot

3D printer: Creality Ender 3 V2

Extrusion system: E3D Hemera

Material: Monster Green SpoolWorks FleXD

Compatible with over 70 different E3D nozzles

Hemera’s custom heatbreak is compatible with the E3D V6 ecosystem, so you can use it with a standard V6 nozzle, Nozzle X, Volcano, or Super Volcano. Why not try:

- BIG 3D prints. Use a Volcano or SuperVolcano nozzle for high volumetric flow, ideal for 3D printers with large build envelopes. Hemera’s high-torque motor and gearing produces extrusion force greater than 100N without losing torque or stripping PLA – that’s more than double the force of similar products on the market.

- Abrasives and composites. Hemera’s hardened steel extruder hobbs are highly resistant to wear from abrasive and composite filaments. Upgrading Hemera to Nozzle X means your 3D printer is ready for carbon and glass fibre filled materials, for serious industrial applications.

- High temperature materials. Hemera’s standard components offer a max temp of 285°C. If you need to go higher, upgrade the thermistor to a PT100 or PT1000, or add a V6 compatible thermocouple and copper block, so you can 3D print industrial high temperature materials like PEEK. As Hemera uses an all-metal design, there’s no need to worry about PTFE going bad.

Hemera was the first all-in-one extruder to market, and still stands up to the competition that's followed it

Precision-engineered for unbeatable torque

Hemera’s 3.32:1 dual drive gears produce over 100N of pushing force on your filament from both sides, for accurate, controlled extrusion without loss of torque. Sharp, individually machined hobb teeth ensure excellent filament grip strength, and round-bottomed profiles help to reduce any build-up of filament debris. The result? High-quality, consistent extrusion from first to final layer.

Compact gears and a custom motor allow the drivetrain to fit within the confines of the motor faceplate. This makes the design smaller, contributing to Hemera’s tight filament path

Each Hemera drivetrain includes shielded bearings and high quality igus® bushings for optimal wear resistance. Lubrication is precisely applied to each drivetrain by robots during assembly, and drivetrains are thoroughly analysed using an accelerated wear test to ensure your Hemera will have many years of 3D printing life.

Hemera’s custom motor end-caps provide convenient T-slots for flat mounting on many popular 3D printers, leaving plenty of room left for other accessories, like bed levelling probes, or extra part cooling fans.

Hemera’s sharp, individually machined hobb teeth ensure excellent filament grip strength, and round-bottomed profiles help to reduce filament debris build-up

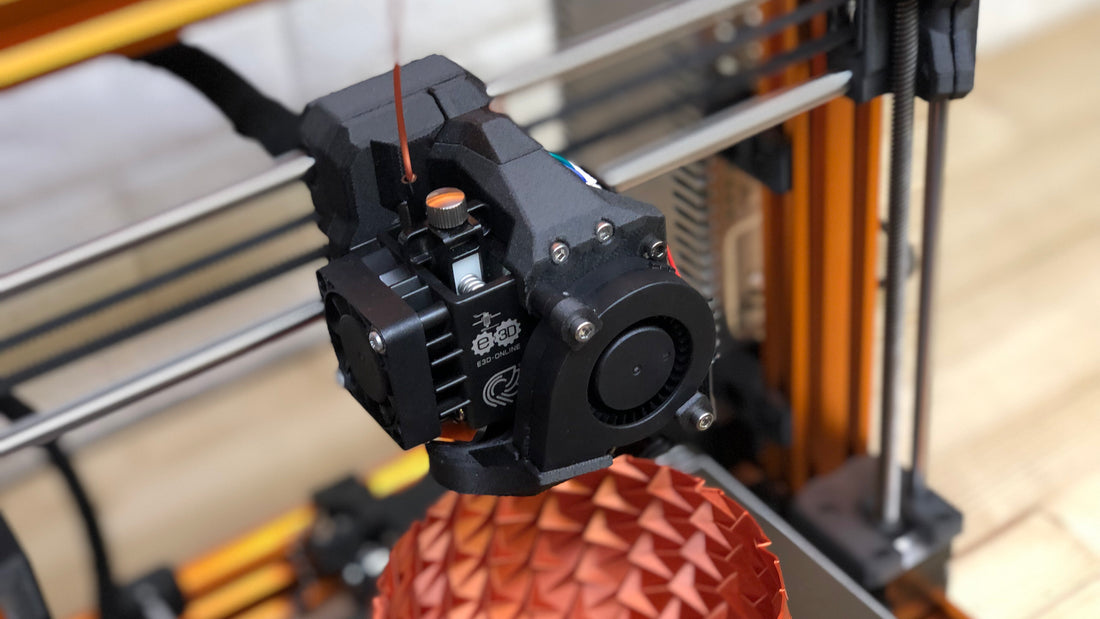

‘The Dragon Egg’ by Loubie3D

3D printer: E3D ToolChanger

Extrusion system: E3D Hemera

Material: Polyalchemy Merlot, Gold Rush, and Nightshade PLA

3D print and photo by Filament Frenzy

‘Voodoo Bree’ by ArteCreator

3D printer: E3D ToolChanger

Extrusion system: E3D Hemera

Material: Fillamentum Green Grass, Vertigo Jade, Mukha, Vertigo Mistique, and Rapunzel Silver PLA

3D print and photo by Filament Frenzy

Custom design for optimal airflow

A common problem with extruders and HotEnds is uncontrolled and unintentional cooling of the printed part, which can lead to uneven stresses and warping. To address this, Hemera has a uniquely designed lightweight aluminium heatsink for highly effective cooling. This heatsink is designed to circulate airflow through the fins and then up away from your 3D print.

Hemera’s heatsink prevents print defects caused by unintentional cooling. It works by circulating airflow through the fins and then up away from your 3D print

Trusted by professionals

The future of additive manufacturing and 3D printing is in the hands of university and private research teams around the world. Academic researchers use Hemera for additive manufacturing research and study, and you’ll find Hemera integrated into well-known 3D printer brands.

‘The Jewel Thief’ by Loubie3D

3D printer: E3D ToolChanger

Extrusion system: E3D Hemera

Material: Polyalchemy Onyx, Abyss, Ruby PLA, Fillamentum Rapunzel, Ivory, and Jade PLA

3D print and photo by Filament Frenzy

Unparalleled product support

Every E3D product includes free lifetime support. E3D customer support agents are on hand to answer any order queries, product questions, or anything else you can think of. Our online documentation includes free Hemera hardware and firmware setup guides for popular machines, and our active community of 3D printing experts are available in real time if you need extra help. You might even talk to the engineers who designed your product!

Hemera is available for sale in over 50 countries via on our online shop, Amazon, and our global network of resellers, so it’s easy to enhance your 3D printer’s performance wherever you are in the world. Buy one today and do more with your 3D printer!