Please note the E3D ToolChanger is now discontinued, story here.

Good news everyone! ToolChanger bundles now ship with Hemera tools, giving you better extrusion and top performance with all materials – especially flexibles. This guide takes a closer look at the key features of the ToolChanger, and some expert reviews from people who have combined it with Hemera tools to make a powerful, reliable, versatile workshop companion.

Why the Hemera upgrade?

We used to ship ToolChanger bundles with Titan Extruders and Bowden V6 tools. We thought it more fitting that Hemera – our latest and greatest extrusion system – features on the ToolChanger by default.

A Hemera Direct Drive toolset on the ToolChanger moves beyond limitations of the old default toolset: using a Bowden setup could lead to flexible materials binding in the tubes, leading to print defects. Hemera’s direct drive configuration has a much shorter filament path and eliminates this issue entirely, so you can enjoy superior performance with all 1.75mm materials.

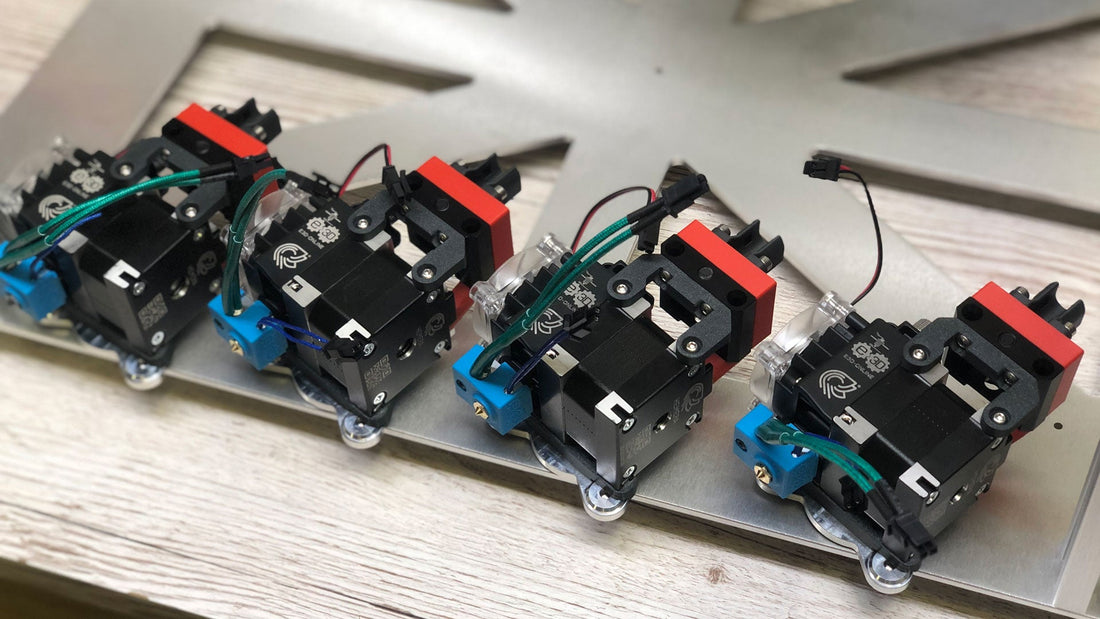

Hemera by E3D, a combined extruder and HotEnd

Four tools, one printer

A ToolChanger is more than just another 3D printer – it can be fitted with a variety of custom tools to enhance your additive manufacturing process in different ways:

- Combine the 3D printing extrusion systems we sell with community-developed rotary milling tools for in-process subtractive manufacturing

- Add custom auxiliary tools like cameras or microscopes for in-process print inspection

- Automate print-in hardware placement with custom pick and place tools

- Add a laser tool head for laser etching

- Add anything else you can think of! It’s a versatile platform

Explore all ToolChanger options

What the experts say…

3D Printing Industry

“The E3D Motion System 3D printer is one of the best workshop companions we’ve ever tested…The remarkable print quality – coupled with the system’s extensive customizability – makes it a potent tool to have in your arsenal.” (Read the full review)

Filament Frenzy (AKA Tom Jackson), power user

“I’m passionate about multicolour 3D printing, and I believe the ToolChanger is revolutionary for this. The ability to change tools removes many of the current multicolour restrictions and opens a great deal of possibilities.

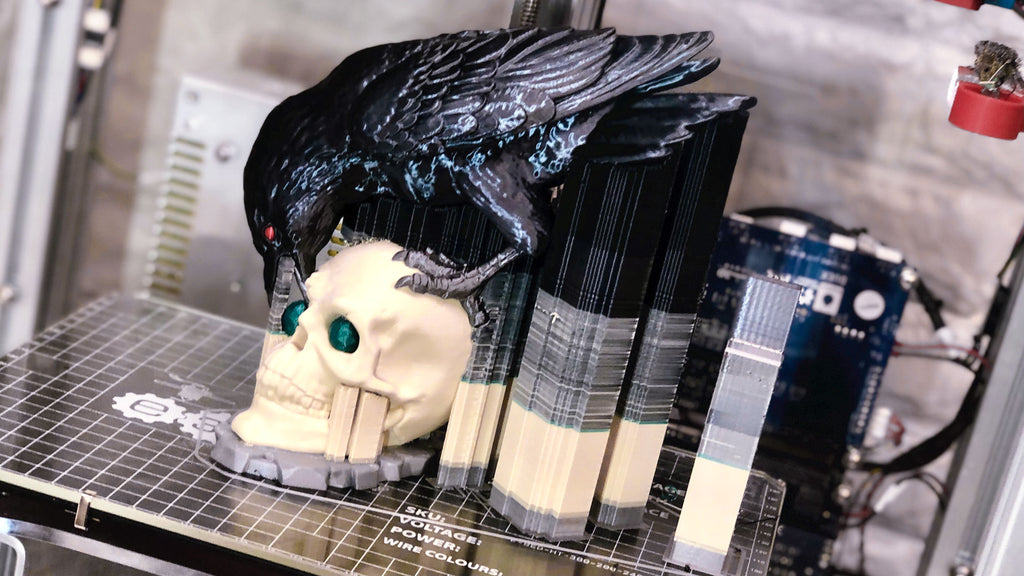

📸Print by Filament Frenzy, design by Wekster

I’ve used other multicolour 3D printing systems in the past, and it can be frustrating because I need to wait around for colours to transition by printing a lot of purge towers. These add time to the process and waste material (and my money!)

Multicolour prints with a ToolChanger are much better; they massively reduce the purge time and risk of material cross-contamination. Combine this into a well-thought-out platform that includes four Hemera extruders in direct drive setup, and you really do have a recipe for success. Hemera takes the ToolChanger from an amazing multicolour 3D printer and turns it into a machine that can print just about any material you can imagine.

📸Print by Filament Frenzy, design by Loubie3D

For me, Hemera’s biggest advantage is the price, because you can put one on a budget 3D printer and get amazing, crisply detailed 3D prints. I’ve owned Hemera since day one and I really believe it to be the gold standard of 3D printer extruders. The precise, short filament path alone is worth its weight in gold. Better compatibility with hard-to-print materials is its biggest accolade: it opens a larger range of filament choice which can be experimented with by anybody, not just the professionals, so it’s easier for people to discover new applications.”

René Jurack, ToolChanger power user

“For me, Hemera is the entire package. The market is flooded with different extruders but when I see an E3D logo I know it’s a quality product for a good price. With my Hemera tools installed on my ToolChanger, I don’t need to tinker around with them and do test prints to get good results – they just work. I can throw any filament I have at them without issue, even carbon fibre and glass-filled filaments.

Extruder tensioning is easy. I’ve printed PLA, PETG, ASA, carbon fibre and more with the same pre-set tension. When I switch filament, I only need to load the tip and the extruder reliably grabs it every time.

Things are open at E3D and there’s a lot of community support, which I appreciate. I can go on E3D’s Discord server or forum to get the information I need directly from their engineers. There’s great after sales support, too. I know I can easily buy clone products, but I won’t get the same quality of support if something goes wrong, and that’ll be my money gone.

René has produced a series of ToolChanger video explainers

CAD files for the ToolChanger are shared in a logical way so I don’t have to spend ages rooting around for the designs I need. A lot of open source hardware projects just share STL files, and these are a massive pain to modify if I want to change something. E3D makes STL, STP, and DXF ToolChanger CAD data available, which I can import into Fusion360 and pull, press, and extrude until I have a part that fits my needs.

I’ve printed lots of things with my ToolChanger, mainly multi-colour objects. By day, I work in the energy sector, and I’ve found uses for the ToolChanger there, too, like production jigs.”

Dr Andy Gleadall, Additive Manufacturing Research Engineer, Loughborough University

“I use a ToolChanger fitted with two or three Hemera tools and we use an auxiliary tool for various applications, such as in-process microscopy.

The ToolChanger is attractive to me because of how configurable the hardware and software is. I’ve written software to create my own GCODE, which enables me to use it for a vast range of research applications. The open design of the ToolChanger, especially the ability to use open firmware and GCODE, is a great asset to my research. Applications such as bioprinting need to run custom GCODE, so an open platform like the ToolChanger is ideal as I can define the object being printed, as well as the position of my microscope tool for analysis. With this, I can inspect deposited material at precise, repeatable locations.

ToolChanger microscopy with custom GCODE designed with FullControlGCODE

I’ve been using Hemera in multiple research studies, and am currently using it to rigorously test the capabilities of our microscale design approach (CONVEX, or CONtinuously Varying Extrusion widths) to characterise how instantaneous changes to parameters such as speed, acceleration, extrusion rate, and retraction enable highly controllable and dynamic variation of the width of extruded filaments (from 75% to 250% of nozzle diameter). The concept has already been proven for multiple materials, layer heights, extrusion temperatures, nozzle sizes, and for both Bowden and direct-drive printer types, the findings of which showed the Bowden printer was an order of magnitude less responsive to changes in extrusion rate compared to the direct-drive printer.

The CONVEX design approach can improve the quality of manufactured parts by eradicating voids and defects, which are known to cause critical stress concentrations in specimens for tensile testing. It can also enable entire new material structures and product types, with feature size-scales perhaps an order of magnitude lower than that permitted by present design rules. This will enable new innovative metamaterials and is particularly appropriate for high-value applications such as advanced filtering, tissue engineering, drug delivery, microfluidics, or electronics, where the geometries of individual extruded filaments (or deliberate inter-filament pores) form the functional design geometry. The responsiveness of Hemera gives us excellent control over extrusion width.

I will be continuing my research using the ToolChanger and Hemera, and I have several other papers involving them currently under peer review. I still have some more Hemera ToolChangers ready to assemble, too!”

BUY A HEMERA TOOLCHANGER

A ToolChanger is cheaper and more capable than a lot of the prosumer machines currently available on the market, and with Hemera tools it can’t be beaten on performance. If you don’t mind some manual assembly and configuration, these people heartily recommend it.