DiamondBack Nozzles

This collaboration combines E3D's decade of extrusion expertise with the hardest material on Earth, delivering the ultimate nozzle solutions on the market. Unlock the possibility of metal and ceramic printing on your desktop FDM printer.

High Performance Diamond Nozzles

DiamondBack nozzles are designed with the ever-increasing demands of fibre, metal and ceramic filled filaments in mind. We have partnered with Diamondback, a US synthetic brand with over 40 years of experience developing advanced Polycrystalline diamonds for drilling tools, cutting tools, and extreme bearing applications where high abrasive resistance and low friction are a necessity.

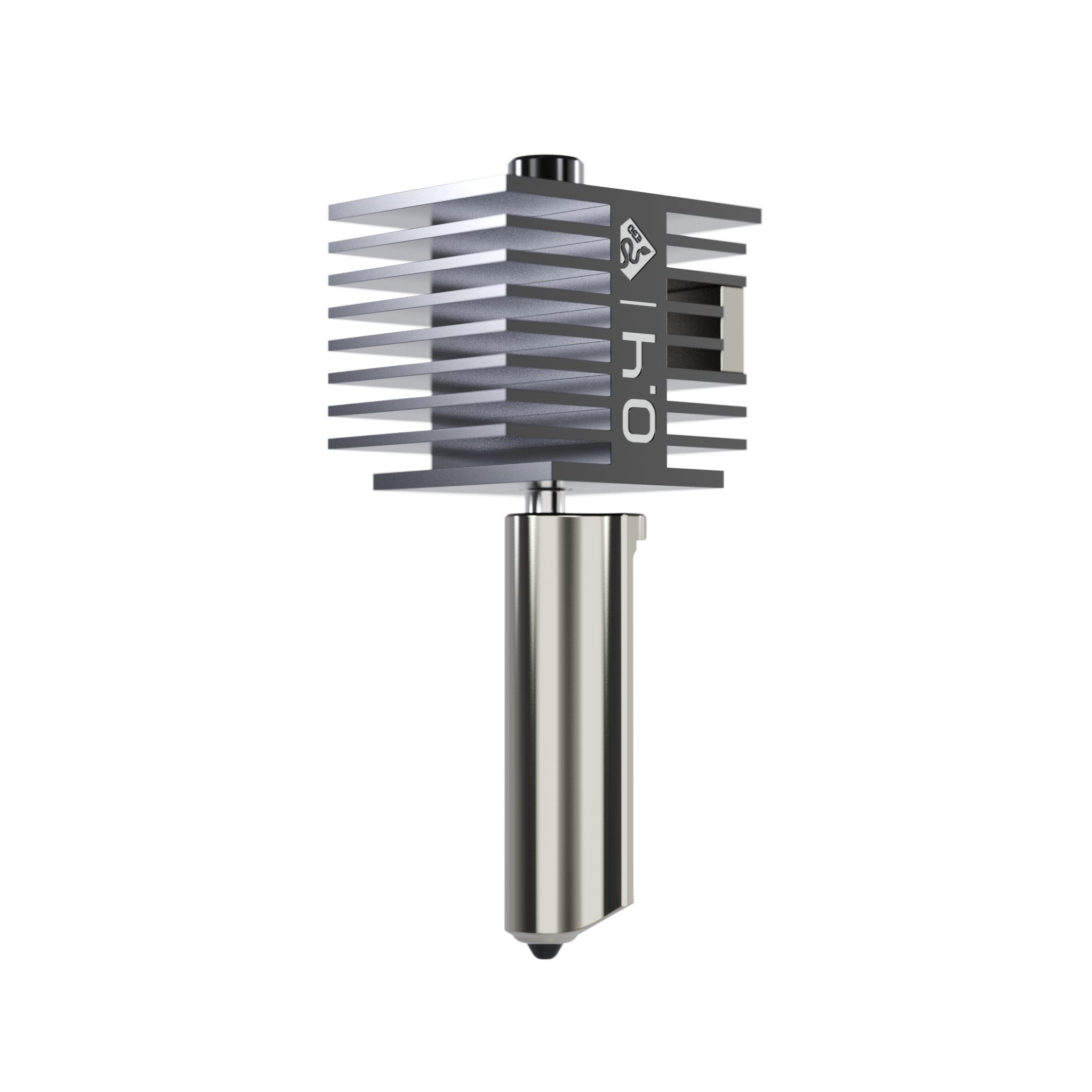

With E3D's 10 years of experience developing industry-leading FDM 3D printing extrusion systems, this collaboration brings you the most extreme nozzle solution you've ever seen. Tool-free room temperature nozzle changing of the Revo ecosystem paired with the hardest material on Earth means you can keep your 3D printer operating at total capacity for longer.

Diamond Vs Polycrystalline diamond

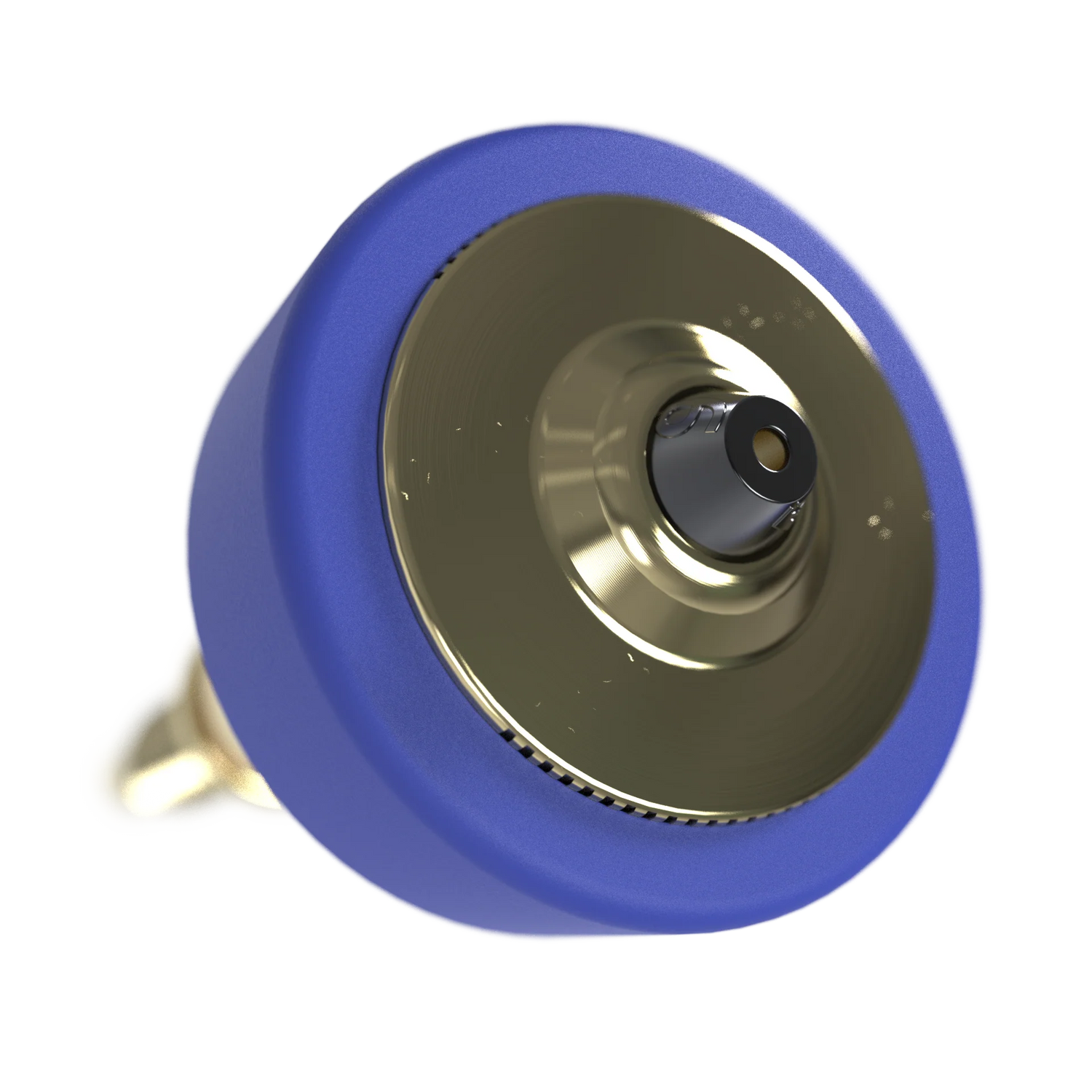

Revo Diamondback nozzles are manufactured from Polycrystalline diamonds, not the typical diamonds you'd see used in jewellery. Traditional diamonds are known for being a single carbon crystal arranged in a specific, repeating pattern, giving the diamond its unique hardness properties. On the other hand, DiamondBacks polycrystalline diamonds are composed of multiple tiny diamond crystals with a proprietary binder that forms a matrix of crystals joined with diamond-to-diamond bonds. Polycrystalline diamonds retain a good portion of the Diamond hardness whilst reducing the inherent brittleness of a single-crystal diamond.

How are Diamonds made?

In nature, diamonds are made under extreme heat and pressure. That's no different to the Polycrystalline diamonds used for these nozzles. To put it in perspective the amount of pressure required is equivalent to the entire weight of the eiffel tower concentrated onto a 5 inch area!

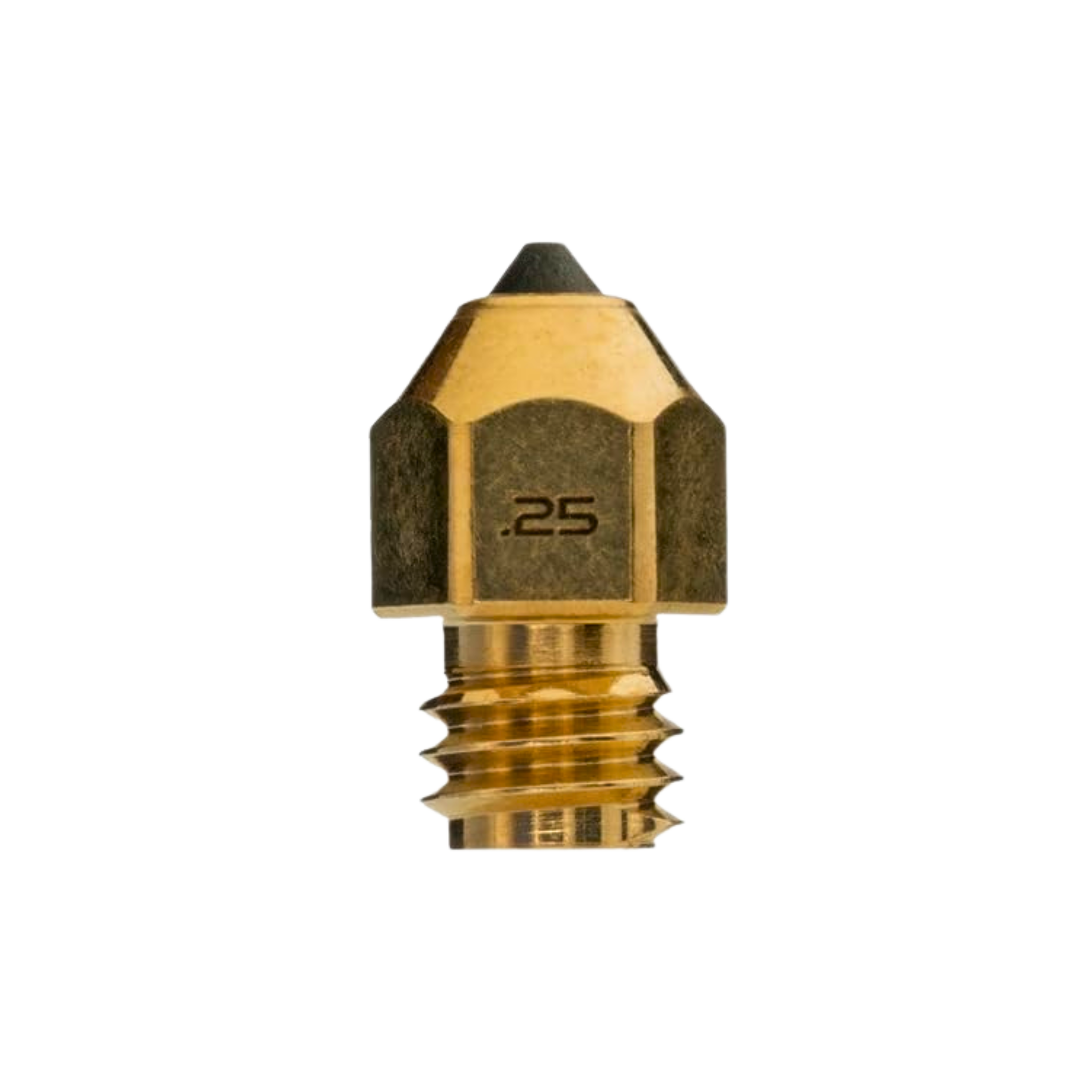

Smooth by nature and design

Polycrystalline diamond inherently has a low coefficient of friction; leaning into the already low friction nature of the material, the nozzle tip is polished to a mirror finish that provides ultra-smooth layers providing a built-in ironing-like property that leaves your top surfaces cleaner than ever.