Description

Higher Flow. Revo™ High Flow increases your setup's volumetric flow rate, enabling you to print faster!

How does this work? Unlike our previous E3D High Flow Hotends (Volcano and SuperVolcano), Revo™ High Flow maintains the exact same form factor as standard Revo HotEnds; this means there is no need to adjust your pre-existing mount and fan duct setups! Revo™ High Flow uses a unique custom internal geometry to increase the surface area for improved thermal transfer to the filament.

More nozzle sizes. Revo™ High Flow unlocks higher flow for existing 0.4mm, 0.60mm, and 0.80mm nozzle sizes and adds 1.00mm, 1.20mm, and 1.40mm nozzle sizes to your arsenal.

Including the standard Revo™ nozzle range, which is interchangeable, Revo allows for a wide range of printing applications with 0.15mm nozzles all the way up to 1.40mm!

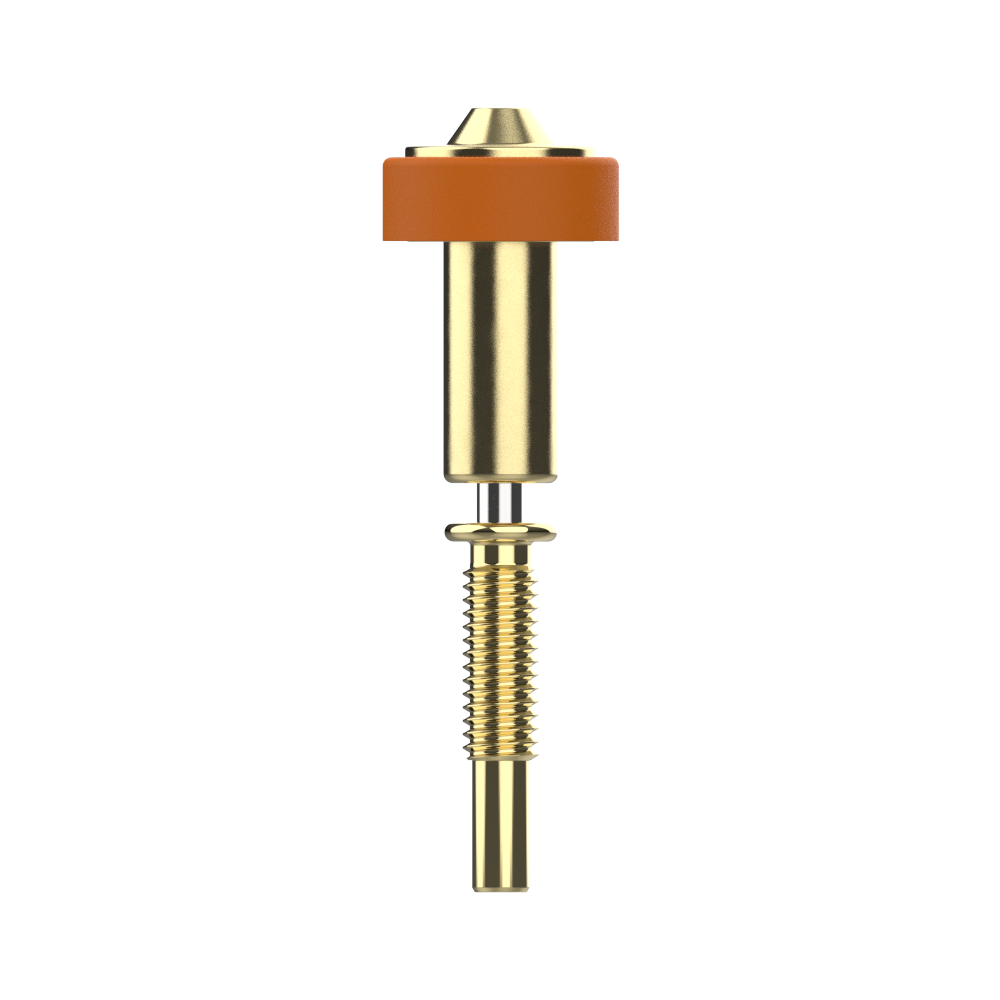

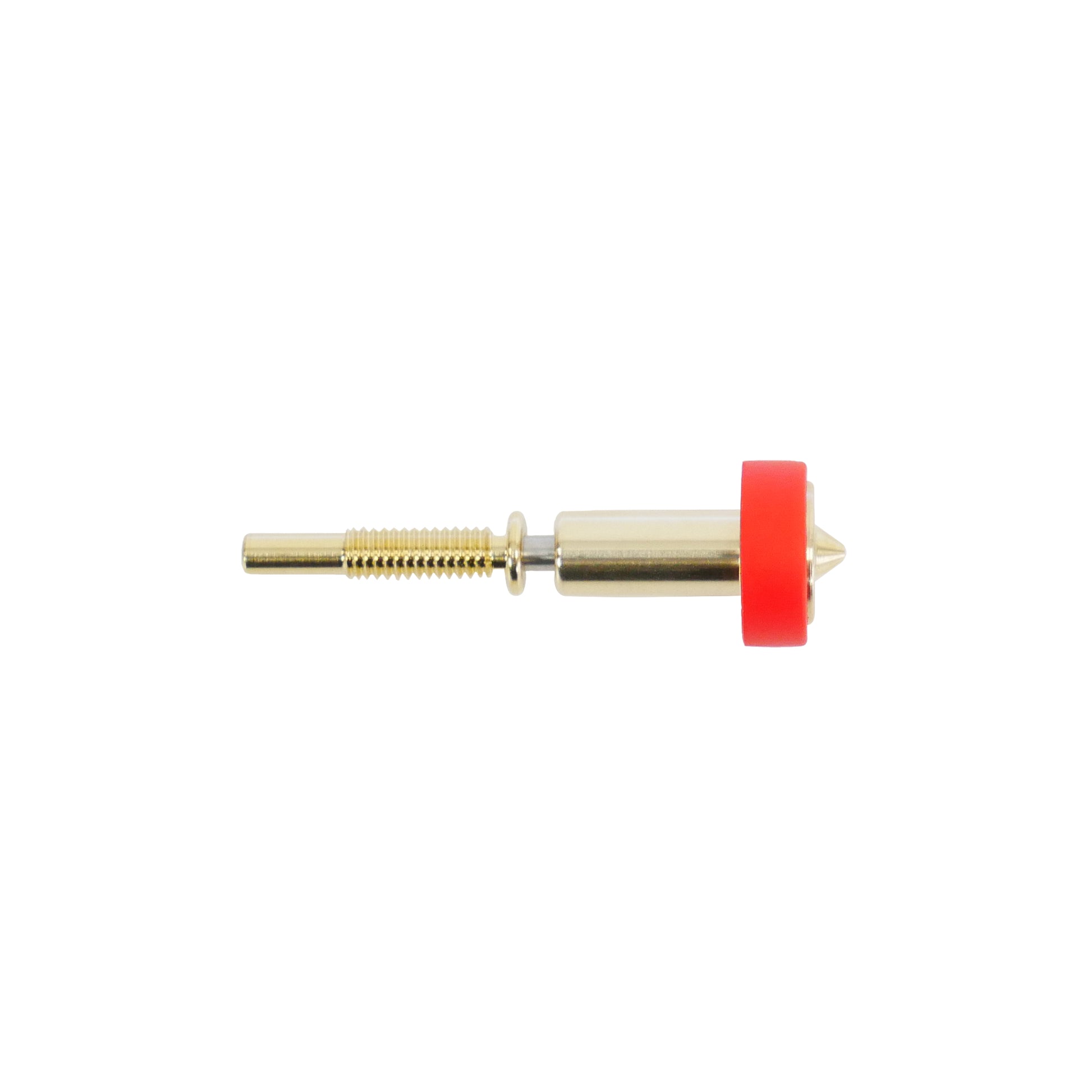

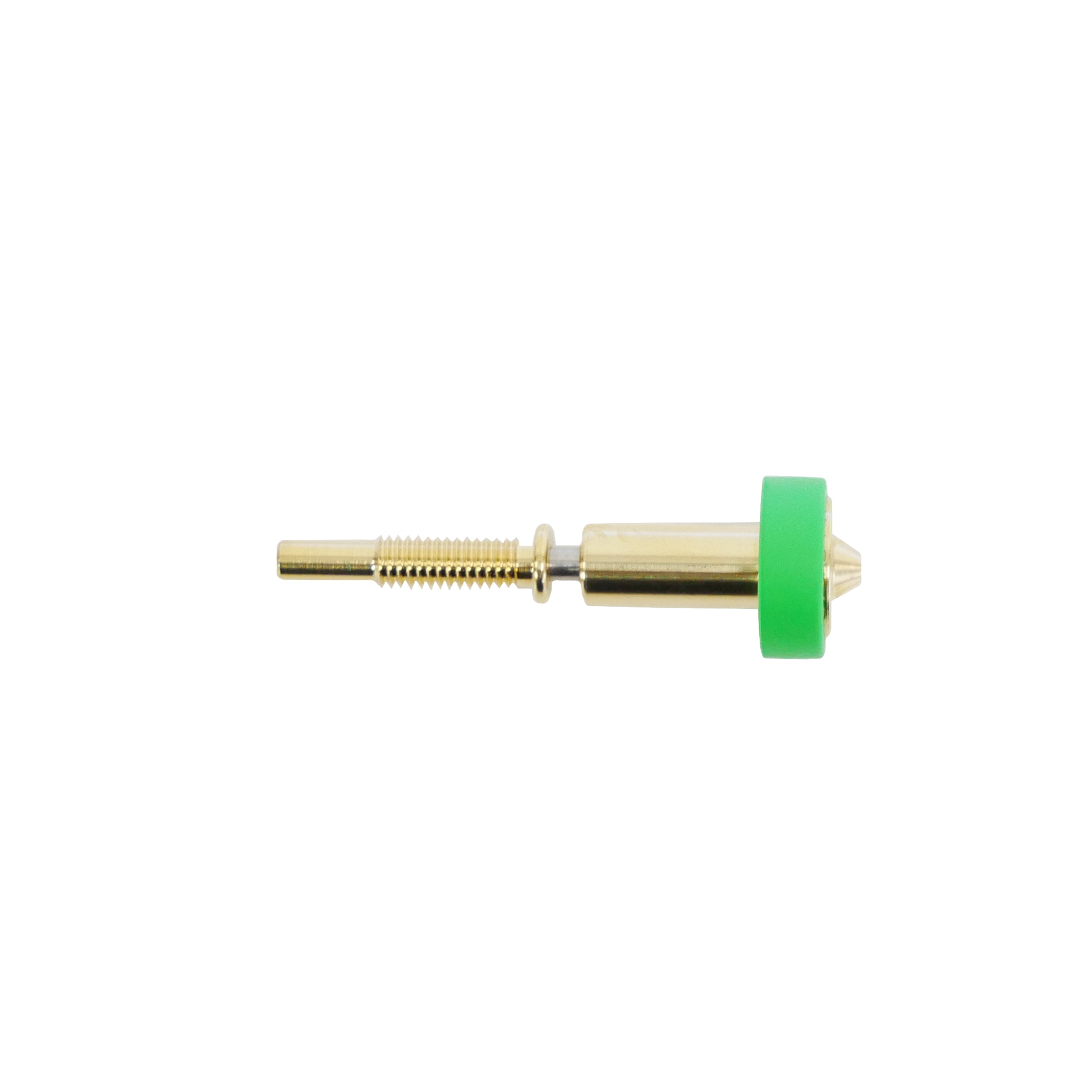

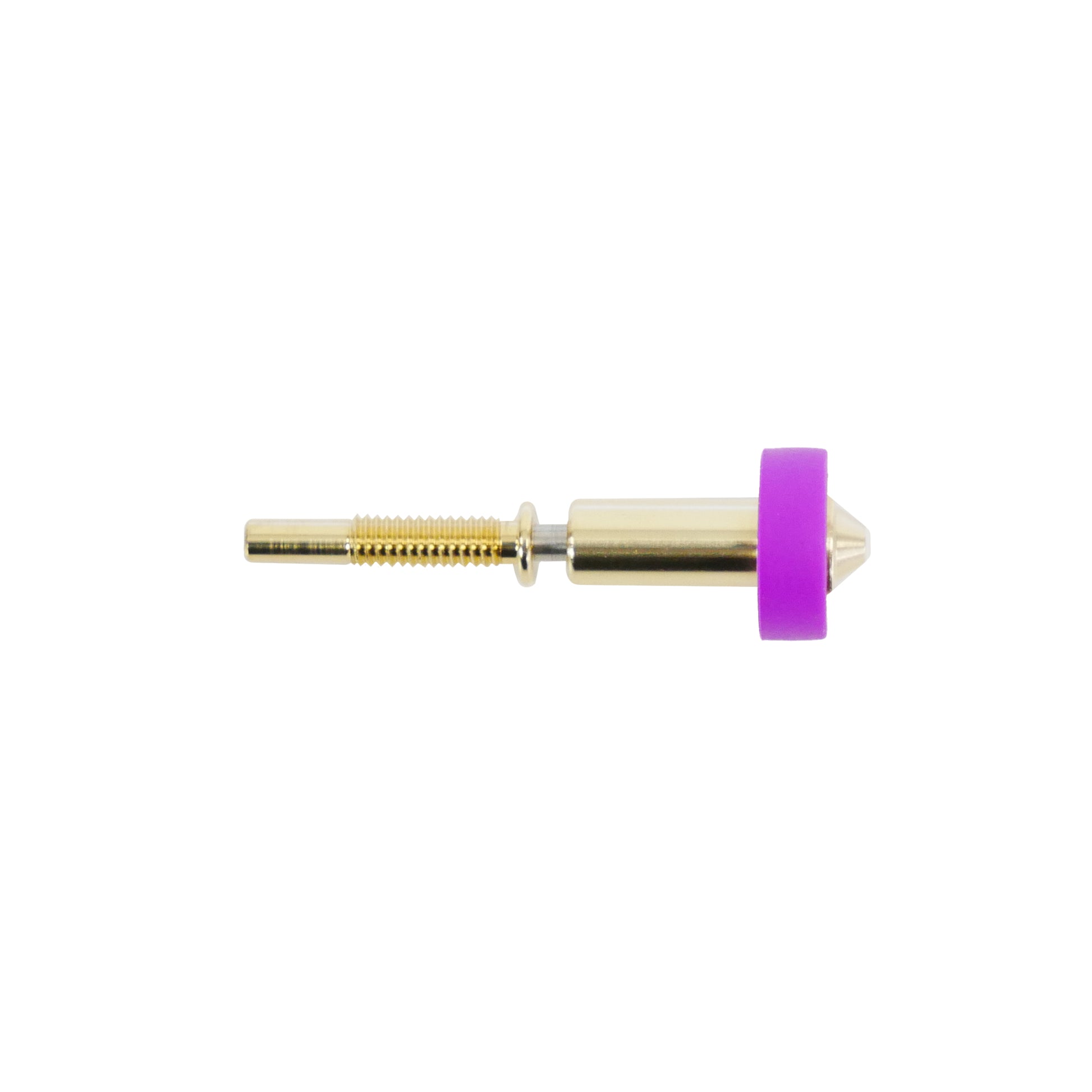

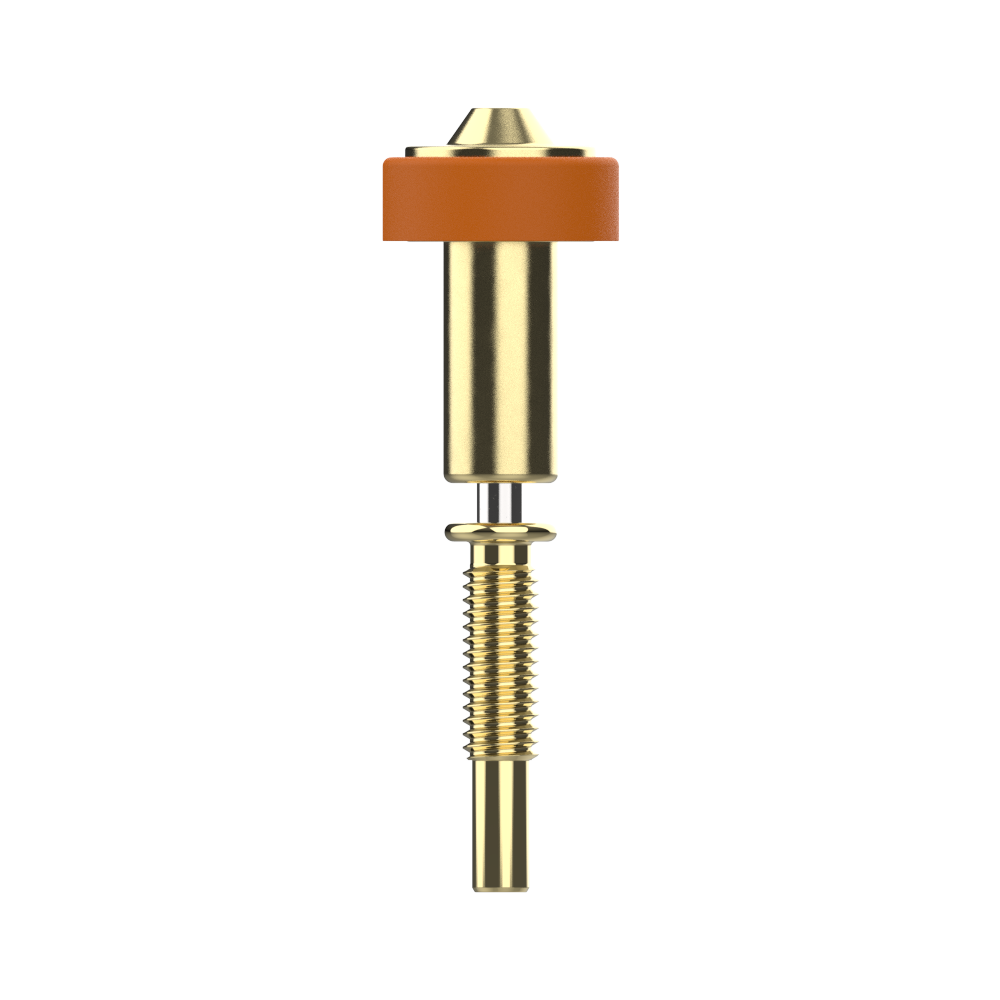

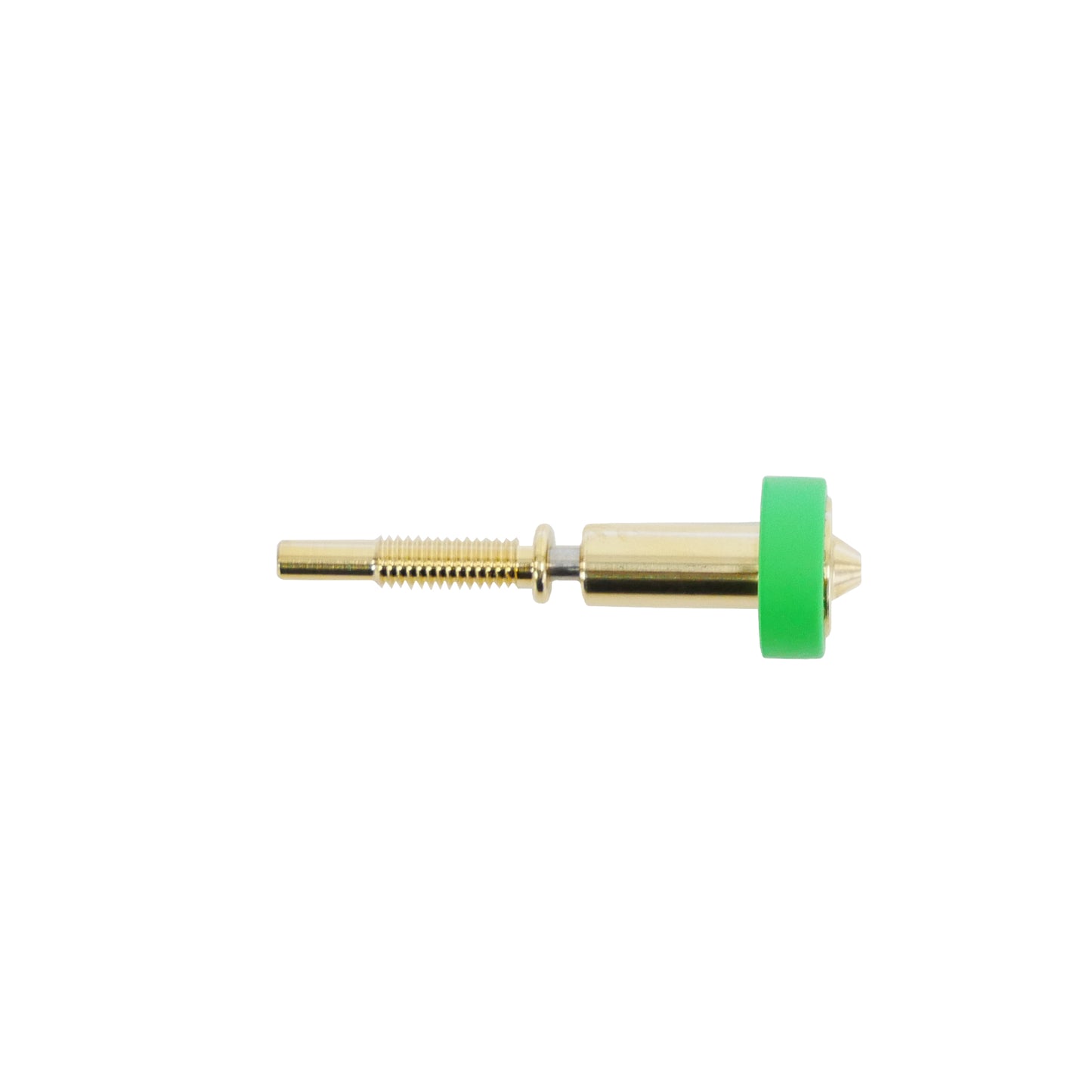

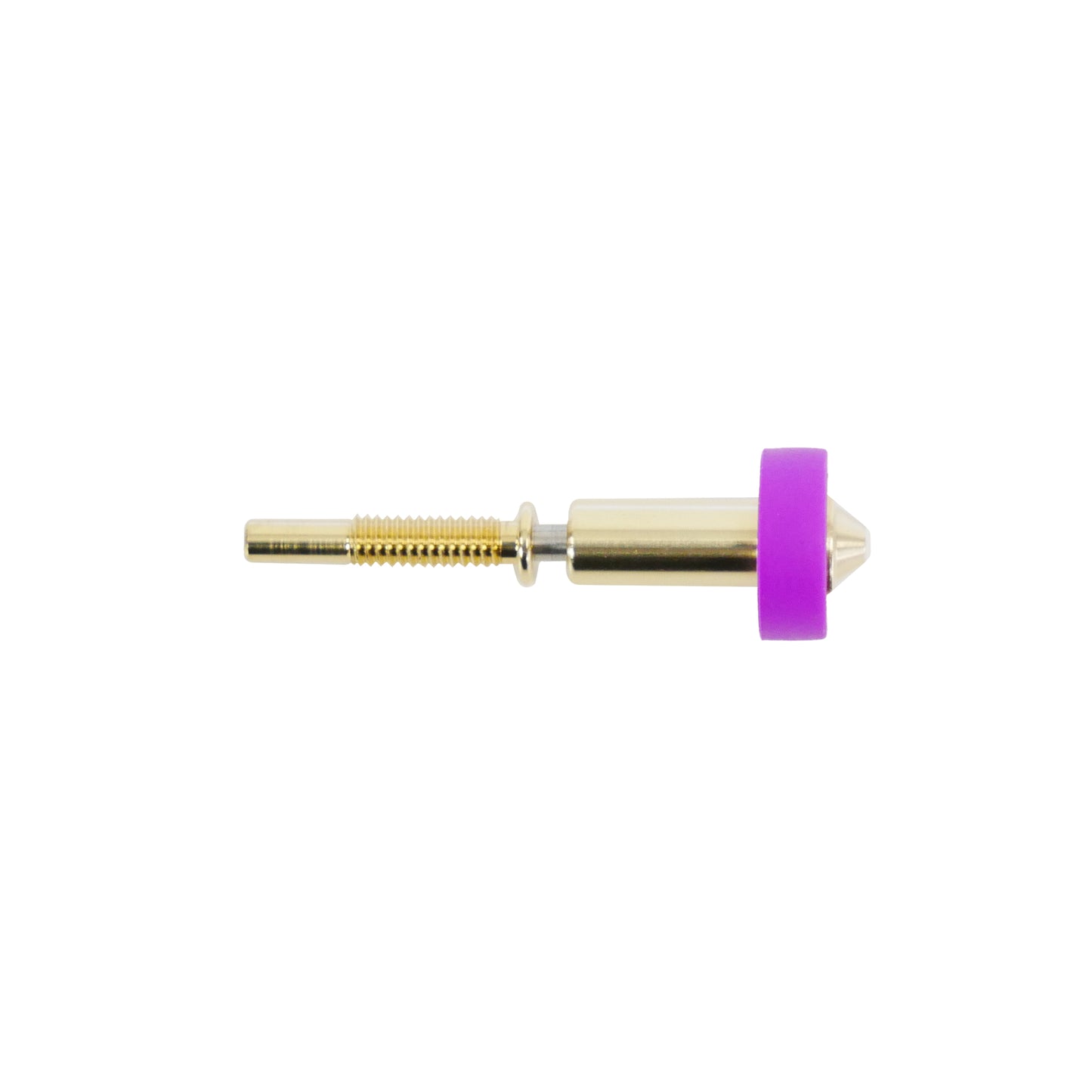

Frustration-free. Each Revo Nozzle is a preassembled nozzle and HeatBreak in one unit, so there’s no hazardous hot tightening and no chance of incorrect assembly. Say goodbye to frustrating HotEnd leaks and enjoy reliable 3D printing!

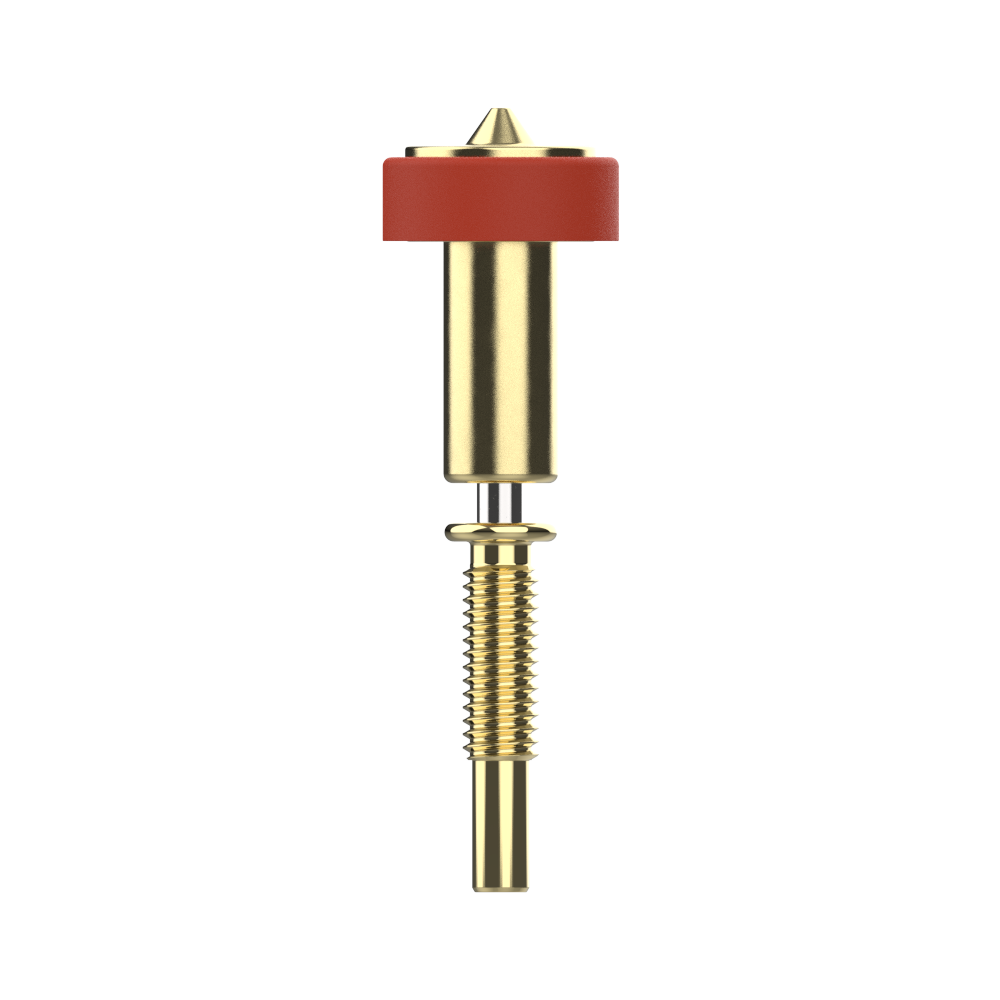

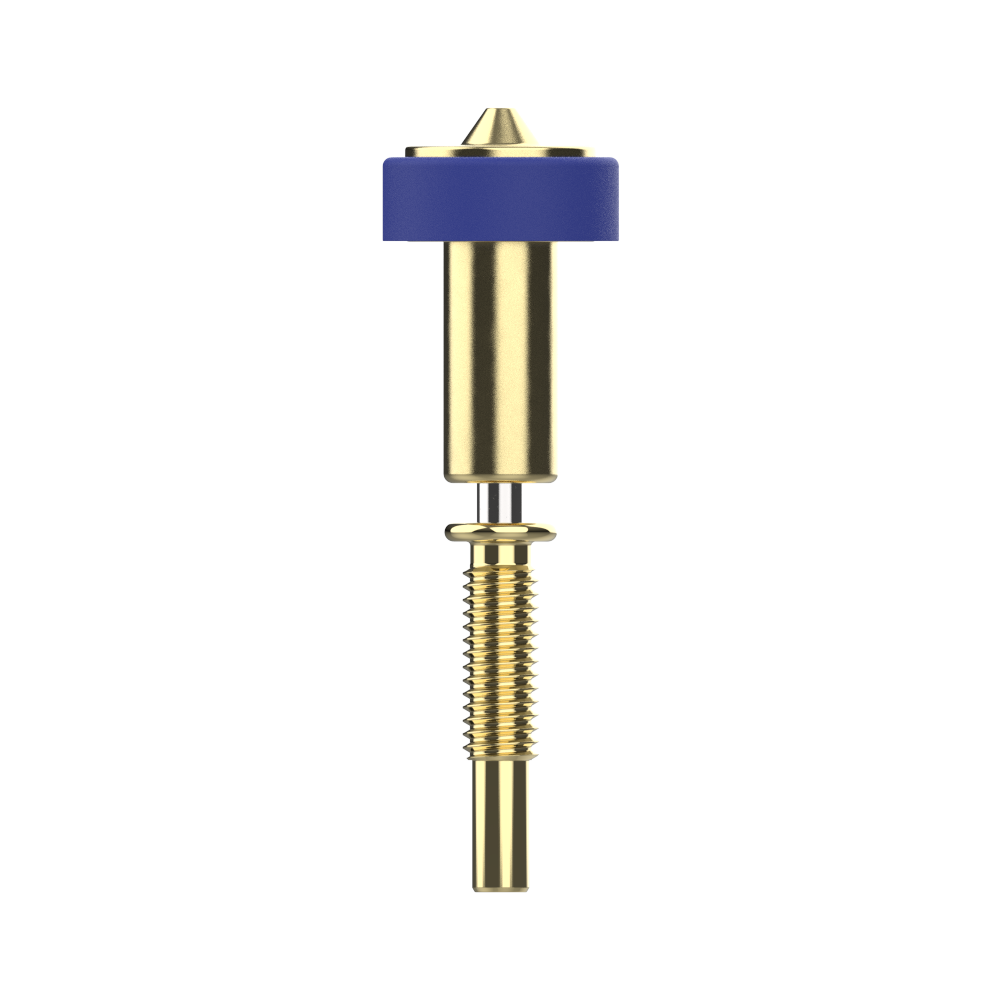

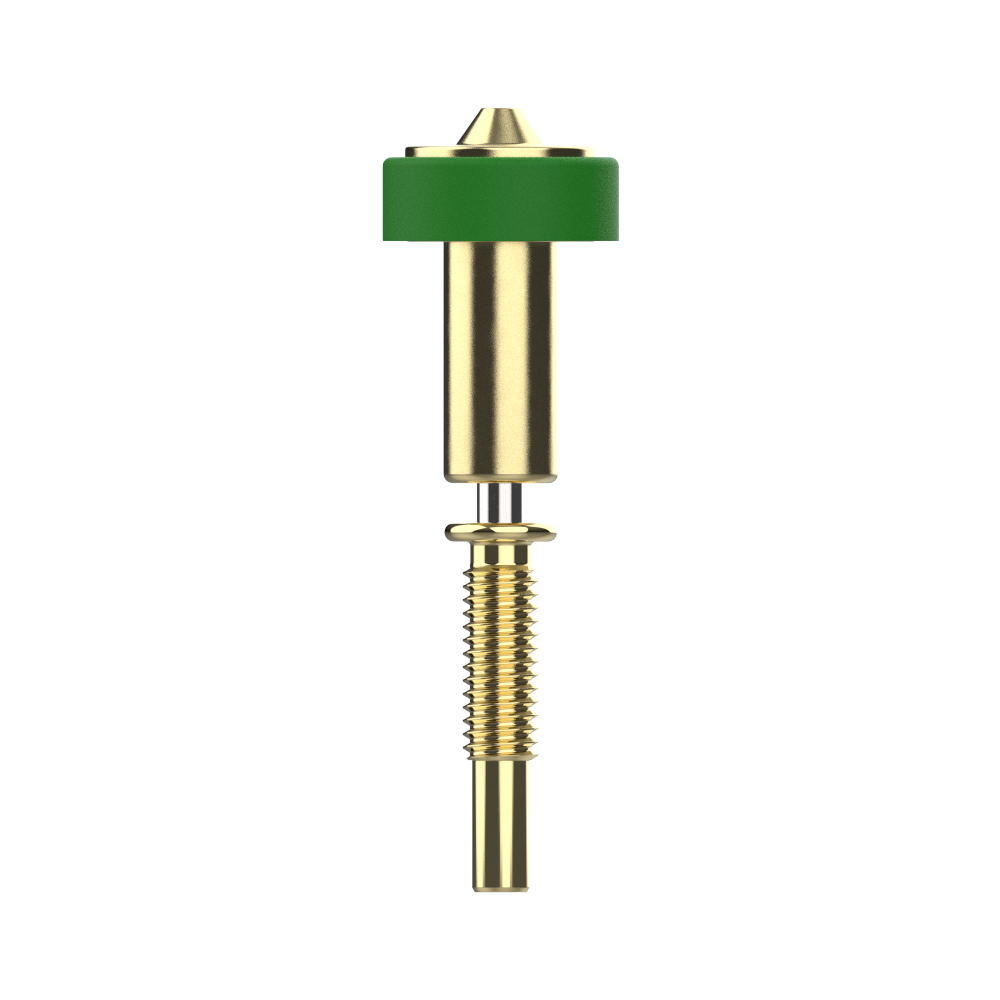

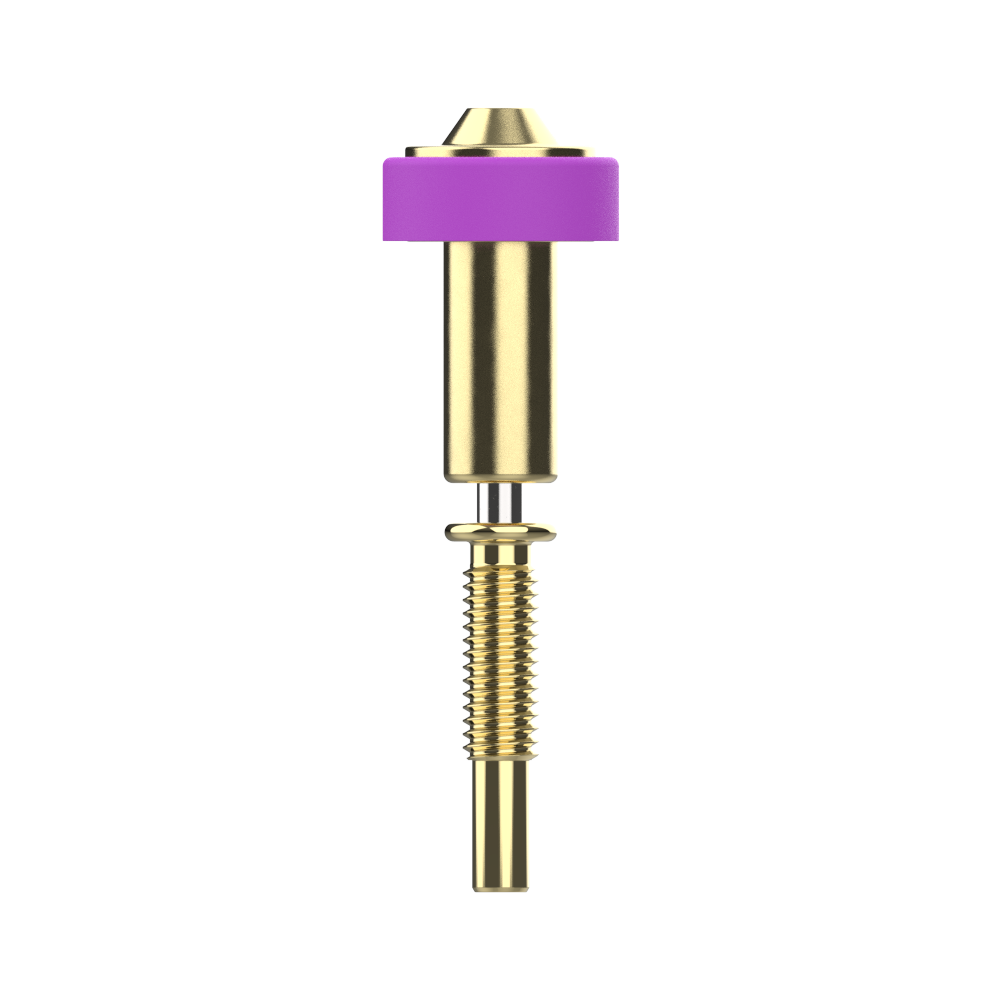

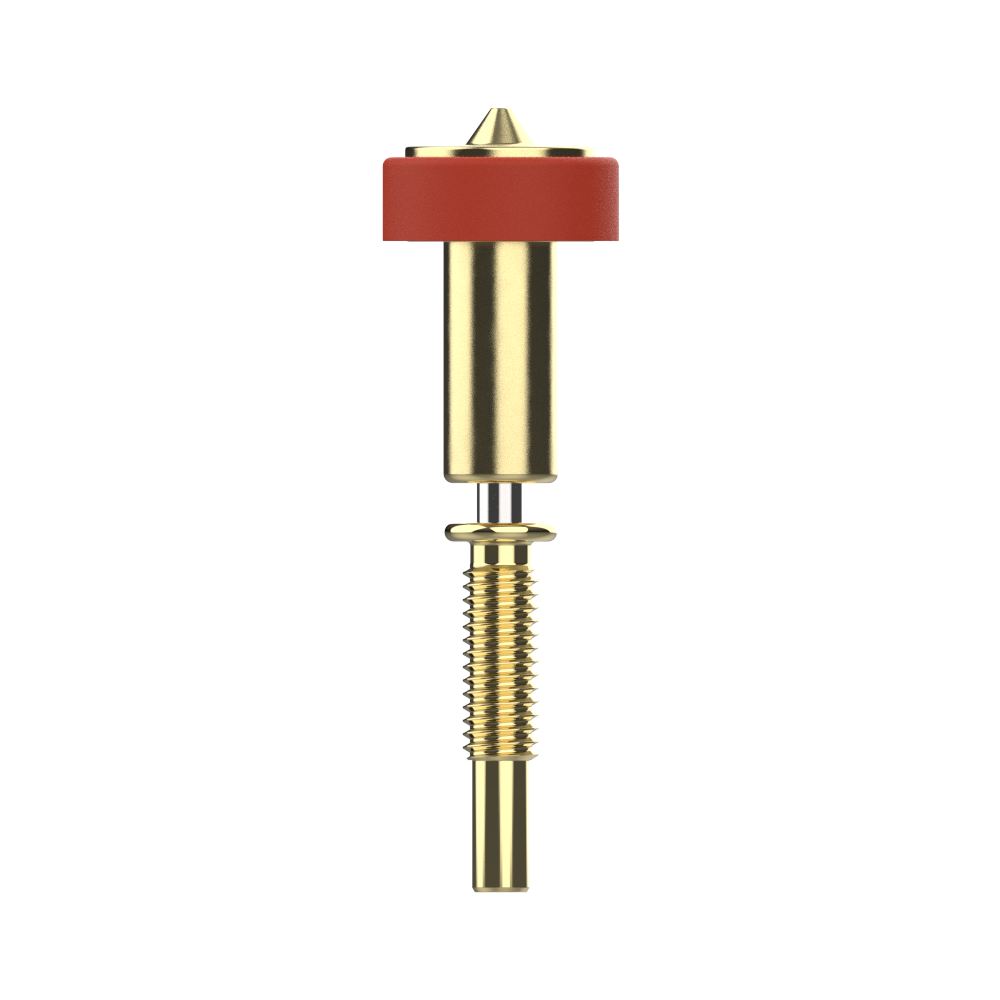

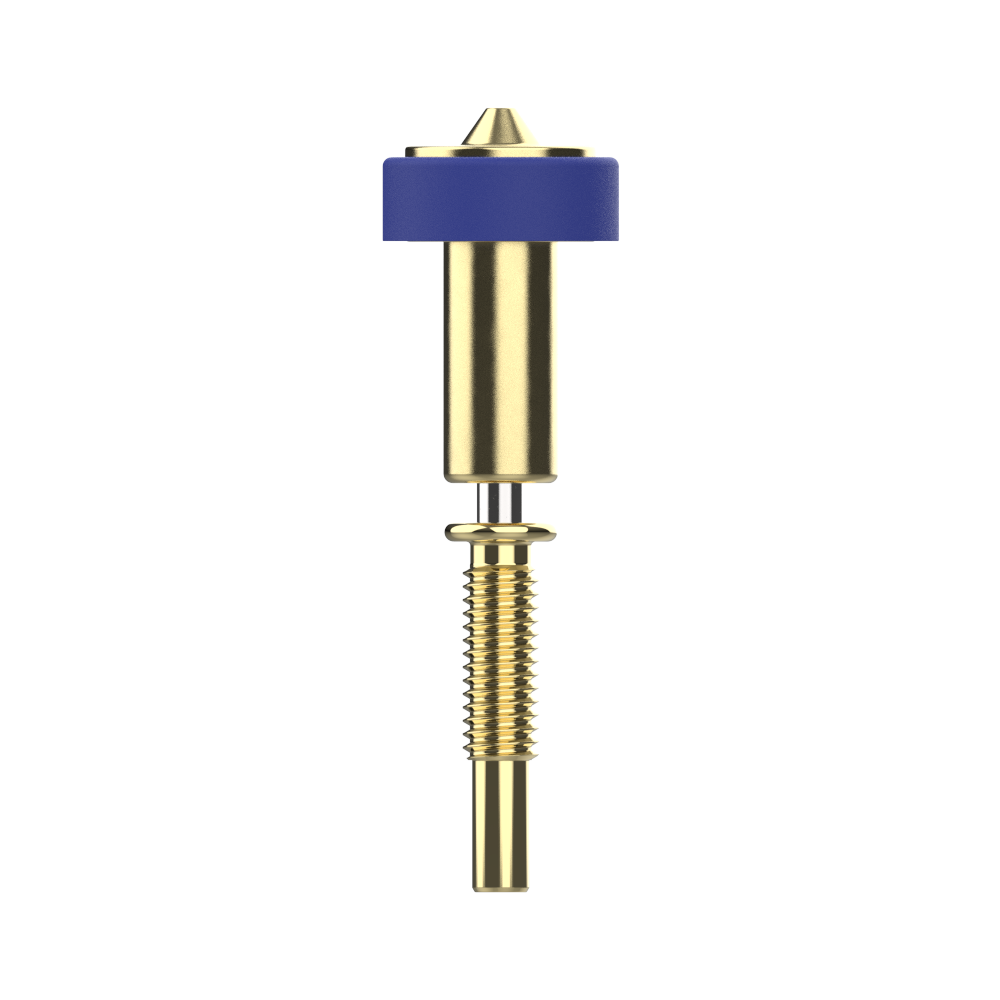

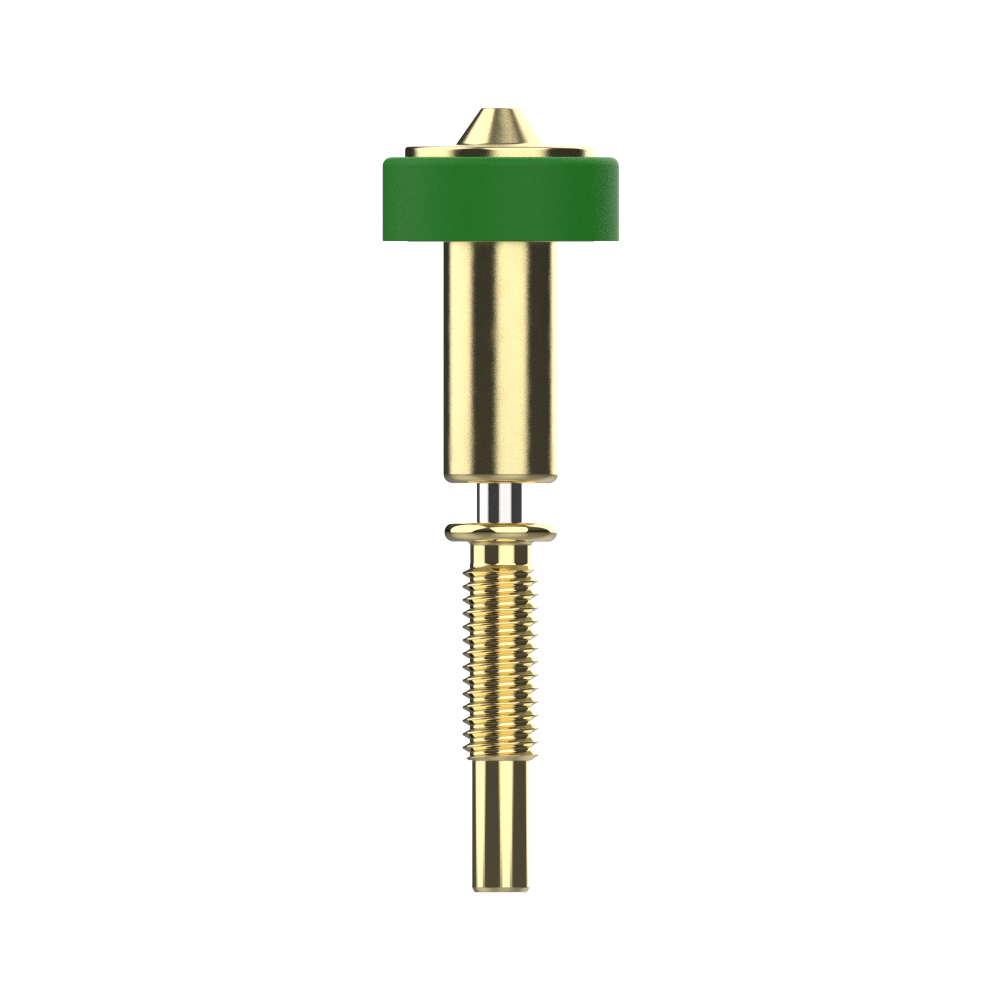

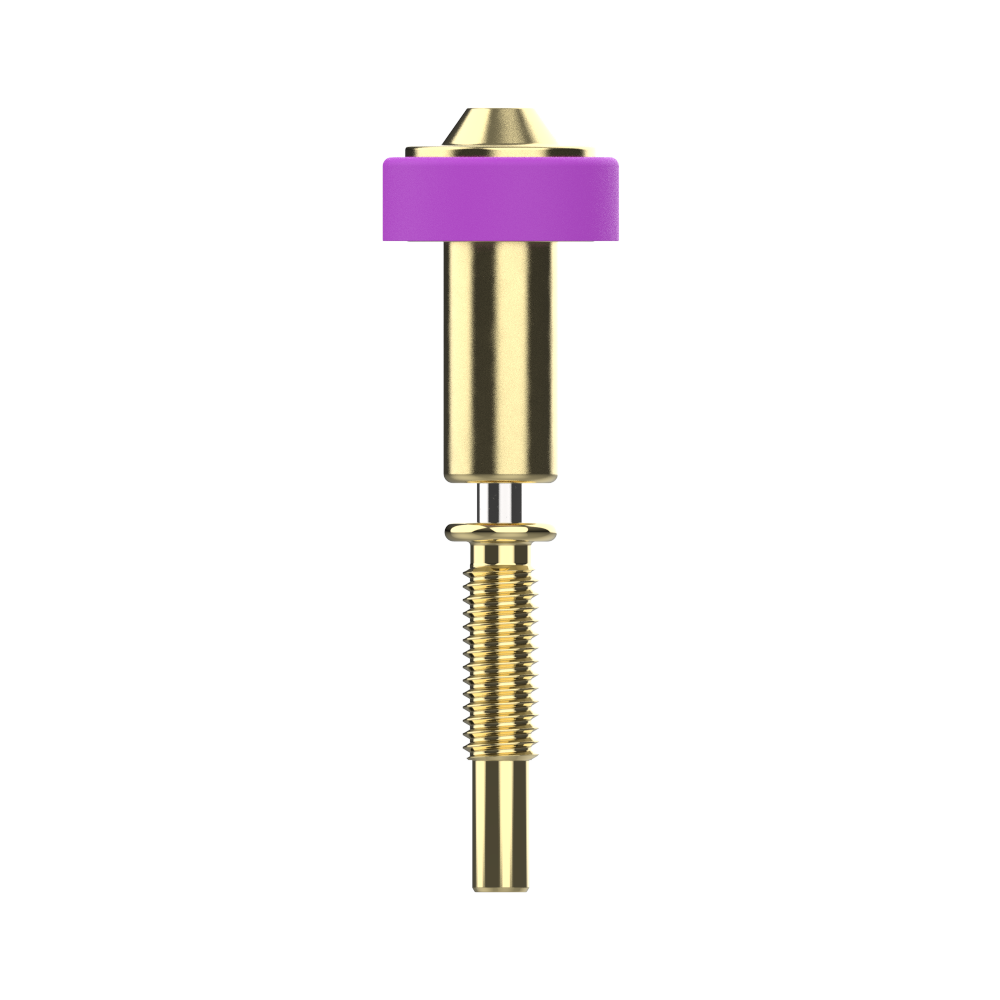

Rapid identification. Identify nozzle sizes at a glance, thanks to a colour-coded silicone sock. Plus, each Revo Nozzle has 'HF' and its size engraved into it with easy-to-read numbers, so there are no confusing identification markers to learn!

Lets talk numbers. Empirically providing useful volumetric flow rate figures is a challenging task. To make our figures as close to real use cases as possible, we have stuck to a semi-standardised testing procedure. For full details on our Volumetric flow rate findings, please refer to our Documentation.

Summary:

It is important to note that when we subject other high-flow hotends on the market to the same testing procedure, the maximum flow rate claims fall short when appropriate print temperature, track widths and layer heights are used.

Similarly, we have benchmarked standard filaments that are not necessarily designed to be used in high-flow situations. If you use HTPLA, PLA³ filament or other specifically high-flow designed materials, the maximum volumetric flow rate you can achieve with Revo™ High flow is seriously impressive!