TL;DR: Without a cold side, it would be difficult to 3D print anything at all! We explore Revo cold sides, plus the strengths and trade-offs of each one.

What's a cold side?!

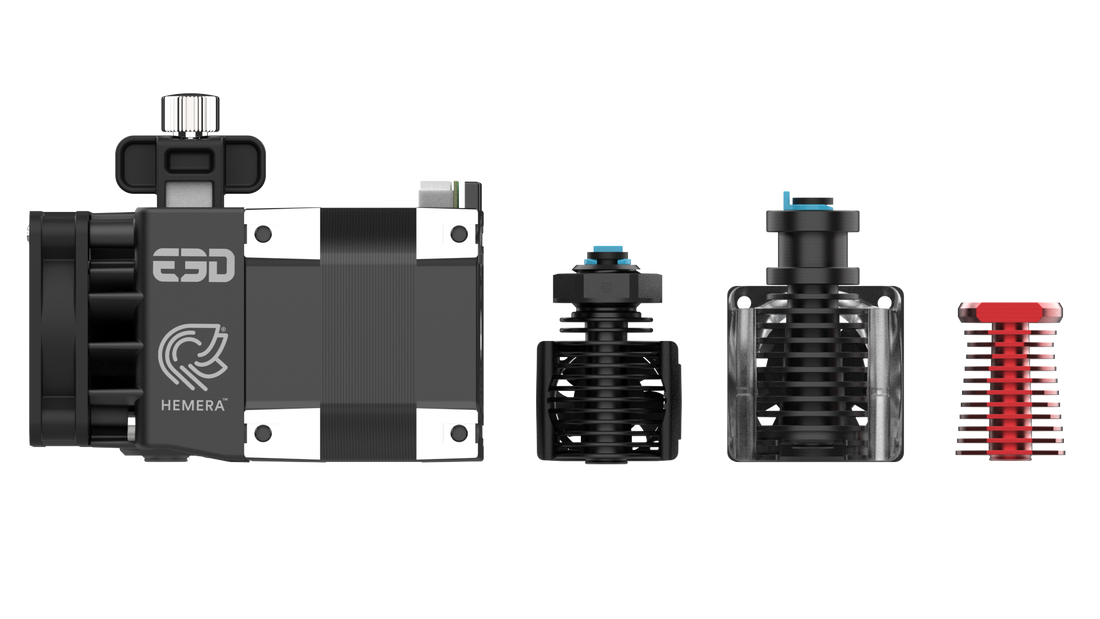

Revo Micro, Revo Six, Revo Hemera, Revo Voron! These are just some of the cold sides we’ve developed as part of our Revo™ ecosystem.

What exactly is a cold side though? In this blog we'll examine the thinking behind them.

Revo Hemera, Revo Micro, Revo Six, and Revo Voron cold sides

Why do HotEnds need to be cold?

Classic HotEnds like the E3D V6 can be thought of in two halves: a ‘hot side’ and a ‘cold side’. These are separated by a ‘HeatBreak’, which does two things: it mechanically joins and thermally separates the two halves.

The most well-known part of a HotEnd is the hot side. This is where material is heated and pushed through a nozzle – an essential part of FFF 3D printing.

But without a cold side, it would be difficult to 3D print anything at all! The cold side is the part of the HotEnd that mounts on your 3D printer. Its primary function is to stop molten filament backflowing up the HotEnd’s filament path. If backflowing happens, this means extruder jams, print failures, machine downtime, frustration, and rage. So, it’s important to have a cold side that can dissipate the heat from the hot side well.

Every HotEnd has a hot side and a cold side

How to stop backflowing

We make our HeatBreaks out of stainless steel or titanium. We do this because these metals have very low thermal conductivity, so less heat will conduct up into the HotEnd’s cold side.

Some heat will invariably find its way into the cold side, and if it isn’t dissipated it will build up.

Budget HotEnds on the market may be able to dissipate heat, but the question is: do they do it effectively? Dissipating heat from the cold side is a dark art. Most HotEnd designs use air cooling, where a heatsink and fan draw away any heat that’s built up in the cold side. We’ve also experimented with water-cooled cold sides in the past, but for most situations we find the most effective cooling method is air: it’s cheap, it’s everywhere, and it doesn’t damage electronics when it leaks.

Too much heat travelling up the cold side causes extrusion issues. We call this ‘heat creep’. In the best case scenario, heat creep will leave your 3D print looking fugly and inconsistent. In the worst case, you won’t be able to print at all and will have a clogged HeatBreak to replace.

We sink hundreds of man hours into validating everything we design to keep the risk of heatcreep to a minimum, so you can enjoy perfectly consistent extrusion with every 3D print!

Revo cold sides: How do they work?

A small lip at the base of each Revo cold side allows you to clip on a Revo HeaterCore retention spring.

Our older V6 ecosystem used a separate nozzle and HeatBreak, which would screw into either side of a heaterblock to form a hot side. Revo works differently: the HeatBreak has been integrated into the nozzle, so you can avoid hot tightening completely. This means you can make nozzle changes using just your fingers – a huge advantage!

Changing a V6 nozzle vs changing a Revo Nozzle on a Prusa MK3S

Inevitably, this comes with trade-offs: our older ecosystems lose compatibility with Revo stuff due to the cold side having a longer and wider hole to accommodate each Revo Nozzle. But cold nozzle swaps and no more hot tightening? We think this justifies it completely! No need to find spanners or other tools to change a nozzle. No hazardous hot tightening. No crispy bacon fingers from touching hot metal.

Revo cold sides come in all shapes and sizes to suit a variety of use cases. Let’s explore what we’ve been working on…

Revo Micro

- Occupies less space inside your 3D printer than a conventional HotEnd

- Thread mounted for less wobble

- Small, lightweight design allows you to squeeze more speed performance from your motion system

- Aluminium construction with black anodised finish

- Tiny, ultra-quiet 5V fan and step down board included

A key component of Revo Nozzles is a stainless steel tube. To make this, we cold draw medical-grade stainless steel (that’s the kind you’d find in an injection needle) to yield a thin-walled tube. This drawing process strengthens the metal and gives it really, really low thermal conductivity – similar to that of titanium. This means we’re able to use a really small heatsink to dissipate heat. The result is Revo Micro, which is the smallest HotEnd we’ve produced so far.

You can leverage the reduced mass of Revo Micro with a Bowden setup to squeeze more speed performance from your motion system. You can also leverage its micro size to win back some build volume (maybe your 3D printer is really small – do you really want a huge HotEnd in there?)

If you prefer direct drive setups, Revo Micro is very easy to adapt to that, too.

M12 x 1.5 thread mounting

We’ve designed Revo Micro with a M12 x 1.5 thread at the top. We’ve chosen a non-standard, fine-pitched thread, for two good reasons:

- A finer thread pitch has more engagement between threads, and therefore tighter and more secure connection

- A finer thread pitch means more threads, so the angle of threads is lower, reducing the chance of loosening while in operation

Following this thread spec, you can easily add a thread directly into your print head design. All Revo Micro cold sides will also ship with a M12 x 1.5 Nylon nut to hold the cold side securely so there’s no wobble.

Keeping things cool

Revo Micro’s heatsink is aluminium construction with a cool black anodised finish. A smaller heatsink needs a smaller fan, so we provide a tiny 5V fan that clips on to the heatsink to keep it cool. 3D printer fans often run off 12V or 24V, so we’ve included a tiny regulator board to step-down voltage so you don’t blow up your fan from overvoltage. Don’t forget to use it!

Revo Six

- Easy drop-in upgrade for any V6-fitted 3D printer (e.g. Prusa MK3S)

- Identical height, diameter, and mounting as E3D V6

- Faster heat up times than an E3D V6

- Anodised black aluminium finish

- Crystal fan duct

Easy drop-in upgrade for many popular 3D printers

The E3D V6 is one of the most widely-used HotEnds in the world. We wanted to make a drop-in upgrade for people who want to keep the form factor of V6, while getting the most out of their 3D printer with the Revo ecosystem.

The Revo Six is a quick and easy drop-in upgrade for any V6 fitted printer, such as the Prusa MK3S. It has the same height and diameter as the E3D V6, with the added advantage of faster heat-up times thanks to the Revo HeaterCore, and rapid nozzle swaps. Use this to your advantage: it means if you have a V6-fitted 3D printer, you won’t need to redesign your print head at all!

Special crystal fan duct!

Of course, you can use your old fan duct when you do your drop-in upgrade, BUT we’re also making new crystal fan ducts so your Revo Six stands out from the crowd.

Revo Six review by Andrew Sink

Revo Hemera

- Integrated extruder and HotEnd

- Simple heatsink upgrade brings your existing Hemera into the Revo age

- Filament pushing force of up to 120N

- Faster heat-up times than classic Hemera

Renovated for the future

We’ve renovated our classic Hemera design for compatibility with Revo Nozzles. A new heatsink has a longer hole to accept Revo Nozzles, and a new lip to clip on a Revo HeaterCore spring.

With this extrusion system fitted, your 3D printer will benefit from extrusion force up to 120N, faster heat-up times from the Revo HeaterCore, and the convenience of nozzle changes without tools or hot tightening!

If you already own a Classic Hemera and want to bring it into the Revo era, all you need is our Revo Hemera upgrade kit. Just replace the heatsink with a Revo-compatible one, add a Revo HeaterCore and screw in your favourite Revo Nozzle!

Flexible performance

Hemera is a top choice for flexible filaments. A tight filament path prevents filament flexing and warping on the way to the HotEnd. With a Revo setup to add to this, it’s easy to 3D print advanced materials and swap nozzles to adapt your extrusion system to different 3D printing use cases.

Revo Voron

We’ve secretly co-developed another cold side with our friends at Voron Design. The result? Revo Voron – the HotEnd of choice for Voron 3D printers!

- Rigid mounting – secures with four M3 screws

- Small form factor and low mass gives your motion system more speed

- Anodised red finish to complement Voron accented parts

- Open source heatsink design (GPLv3)

Ready for Revo

Revo Voron is 100% compatible with our Revo ecosystem, so you can change nozzles rapidly at room temperature without tools or hot tightening! Print with 0.25, 0.40, 0.60, and 0.80mm nozzles simply by screwing in with your fingers. A velvety-red anodised finish adorns the aluminium construction to complement Voron’s distinct colour scheme.

Four M3 screws keep Revo Voron firmly mounted in place, and like other cold sides, a Revo HeaterCore clips onto a lip at the bottom. This cold side is supplied without a heatsink fan because it’s designed for use with the VORON Stealthburner, which incorporates a heatsink fan already. That’s not to say it won’t work with other 3D printers as well – just remember to keep the cold side cool, otherwise: heat creep.

Revo Voron is slated to ship after we fulfil our Revo pre-orders, which is estimated to be after March 2022. Not long now!

Guess what? More secret Revo cold sides beyond these are in the works for some of the most popular 3D printers on the market. You’re in for a treat 😉

Learn all about Revo

You can already review Revo documentation in the E3D Help Centre. Follow our blog, join the conversation on Discord, or follow our socials to be the first to know about Revo announcements!