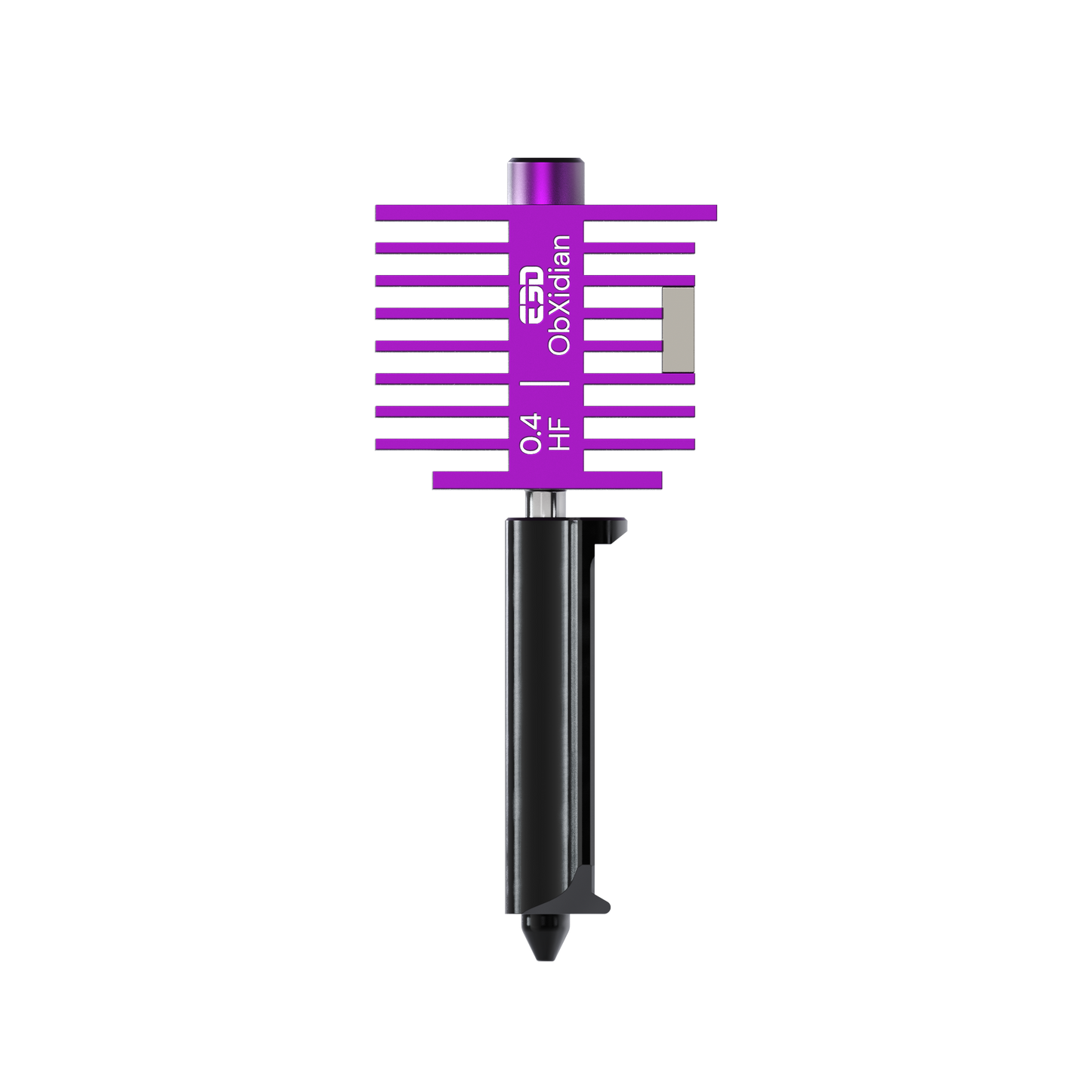

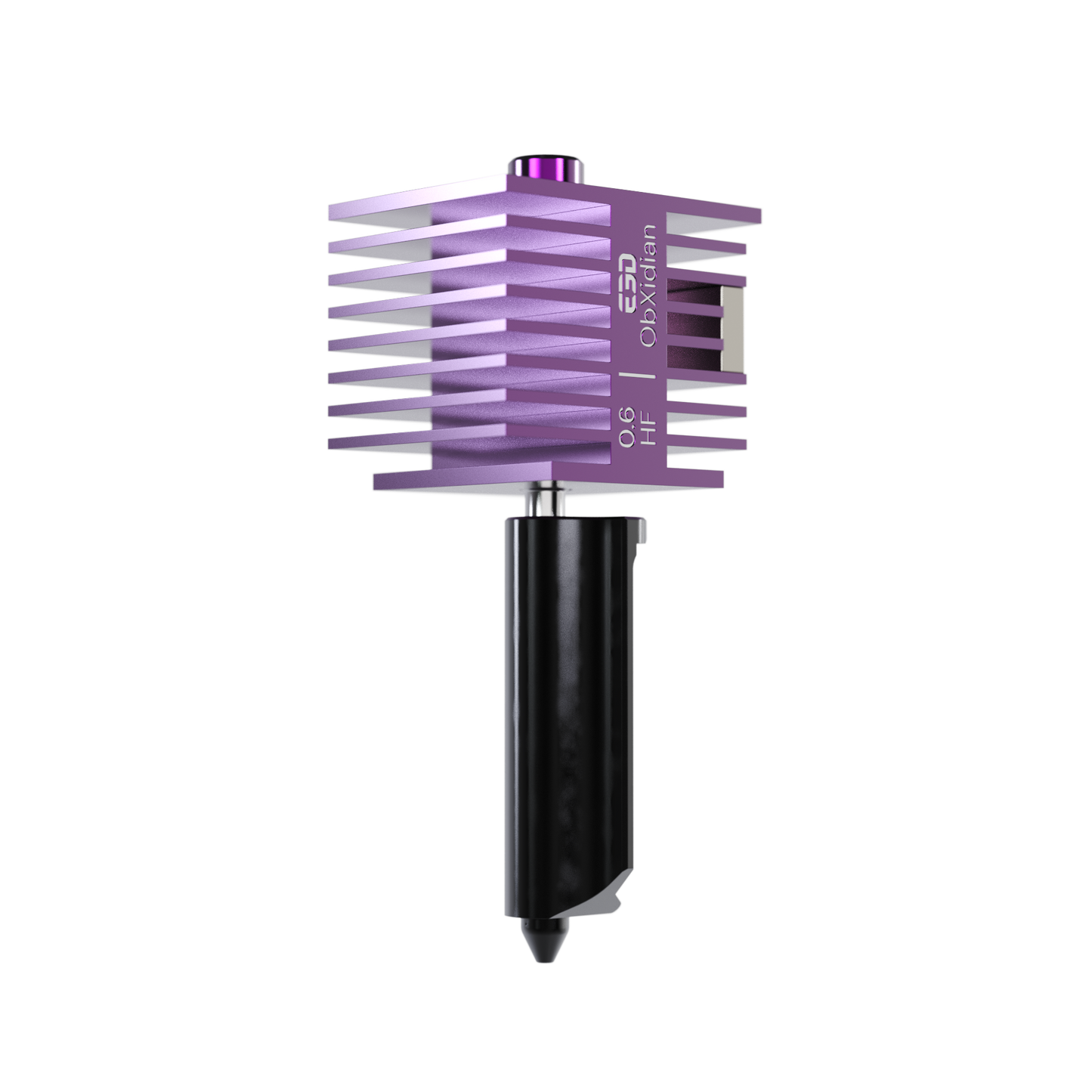

Description

These premium HotEnds are an official collaboration between E3D and Bambu Lab. The E3DLC™ coated nozzles are exceptionally wear resistant and significantly outperform other hardened nozzles allowing your A1 to print notoriously tricky filaments with ease. E3D are very proud to be the only officially approved manufacturer of aftermarket Bambu Lab HotEnds.

High Flow

The internal nozzle modification of this HotEnd means you can increase your volumetric flow rate by up to 70%! That means you can expect more reliable and consistent extrusion at the same speeds or bump up the volumetric flow rate limit in the slicer to utilise the motion systems' capabilities fully.

Smooth and Strong

High-speed printing often sacrifices visual and functional aspects in favour of speed but these HotEnds maintain interlayer adhesion strength even at higher speeds; resulting in the perfect filament finish and strong parts for functional applications.

Non-Stick Coating

The state-of-the-art E3DLC™ coating applied to the nozzle prevents plastic buildup. This will drastically reduce the likelihood of print crashes and limit the amount of cosmetic defects in your prints.

Long Lifespan Nozzles

Our ObXidian® technology significantly extends nozzle life because the nozzle is several orders of magnitude harder than other steel nozzles on the market. Better for your pocket, and the planet.

Effortless Upgrade

These magnetic HotEnds couldn’t be easier to install. The heater and temperature wires are built into the toolhead so all you need to do is unclip the existing HotEnd, slot in the new one and you’re good to go. No physical adjustment to the mount or part-cooling is required.

Buying Outside the UK?

Avoid additional charges and lead time by ordering from your local E3D Reseller.

E3D gives a small royalty to Bambu Lab for every sale of this Bambu-approved A1 upgrade. Bambu gives all this license fee back to the community, and is generously donating 50% to the Sanjay Mortimer Foundation, a charity set up to support young neurodiverse people with a talent for engineering.

Please note:

- ObXidian® nozzles are exceptionally wear resistant compared to other products on the market and significantly outperform other hardened nozzles. Improvements in ‘exotic’ engineering filaments mean that some new materials which include aggressive fillers, including but not limited to Polymaker’s Fiberon range (PA612-CF, PA6-CF, PA6-GF and PA12-CF), can cause significant wear on even ObXidian® nozzles. E3D is actively developing even more specialist solutions for these materials. In the meantime please be aware that your ObXidian® nozzle will not be everlasting under extreme material conditions.

- Some filled materials contain particles that are close to, if not larger than, some of the smaller industry standard nozzle sizes, including up to 0.4mm. Attempting to print such materials through these nozzle sizes significantly increases the risk of a jam. Please check your filament manufacturer’s datasheet for recommended minimum nozzle orifice diameter to ensure that the nozzle/HotEnd you choose is suitable for your use case.

- On the A1 and A1 Mini 45mm3/s is the maximum volumetric flow rate possible for a 0.4mm nozzle under E3D’s test conditions. This is derived from the maximum motion system speed of an A1 printer (500mm/s), a track width of 0.5mm and a layer height of 0.2mm (both of which are kept constant for all 0.4mm tests). Increasing the commanded flow rate above this value has no effect as the speed is restricted by the motion limit of the machine.

- These HotEnds are not compatible with the Bambu Lab H2 Series printers.

- The actual time savings you will see will be influenced by the print settings used, as well as the print design itself.