E3D’s purpose is to change the way that humanity manufactures goods by bringing 3D printing innovations into the market. We’re excited to share the latest one with you.

E3D’s RapidChange™ family

Subtractive manufacturing has had the ability to change tools quickly and easily for decades. It’s about time additive caught up. Today we introduce the first member of E3D’s RapidChange family – Revo.

Revo is a revolutionary ecosystem that builds on everything you loved about E3D V6, while making it easier to use and better in almost every respect.

RapidChange – Freedom to use the right tool for the job

RapidChange Revo enables you to rapidly change nozzles, making it easier to use the right tool for each job or material. Simply unscrew the nozzle with your fingers at room temperature, and then screw in a new one. That’s it – no tools, no hot-tightening, no fuss.

Ultra-lightweight – Move faster

Revo™ Micro is half the mass of the E3D V6. Its design has been optimised for space and weight, so it occupies less space in your 3D printer, and reduces the mass on your printhead to help you print faster.

Rapid identification

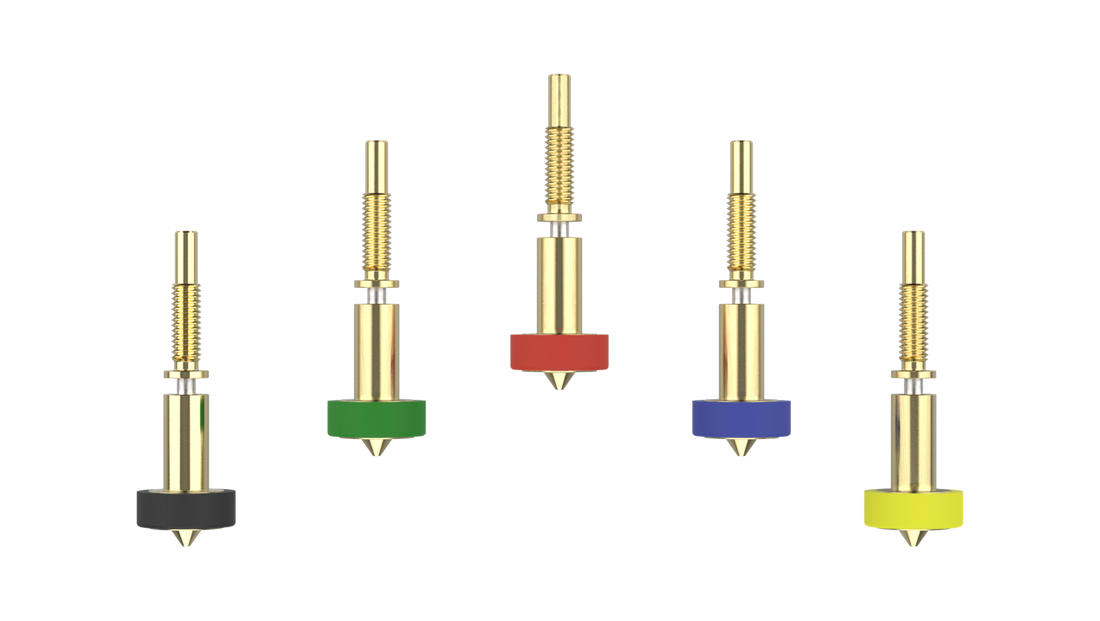

Each nozzle variant is fitted with a colour-coded silicone sock, so you can identify nozzles at a glance. You’ll also find the size engraved under the sock for easy identification, so there are no complex identification codes to learn.

Revo nozzles will have four sizes at launch, with more types and sizes to follow

Minimal downtime

If your nozzle becomes blocked or jammed, simply swap out for a new one. Each nozzle change refreshes the area that’s been in contact with molten plastic, so you can get back to 3D printing with minimal machine downtime. Because the nozzle and HeatBreak are integrated into a single unit, there’s zero chance of plastic leaking.

Engineered for safety

We’ve developed an entirely new heater technology for Revo. Our compact new HeaterCore is smaller, neater, and more robust than traditional heater blocks. It's designed with a positive temperature coefficient (PTC) that reduces power as it gets hotter, drastically reducing the maximum thermal runaway temperature and associated hazards.

Left: an old heater, thermistor, and block setup

Right: Revo HeaterCore

Leverages 10 years of innovation from E3D

We understand the fundamental physics of extrusion systems for FFF 3D printing better than anyone else, and we’re proud to have poured everything we know into this exciting new ecosystem. Read on for the technical details, information about pre-orders, and FAQs.

Technical specifications:

- Max temperature (out-of-the-box): 300C

- Nozzle sizes at launch: 0.25mm, 0.4mm, 0.6mm, 0.8mm

- Nozzle materials at launch: Brass

- Wattage: 40W PTC

- Voltage: 12V or 24V

Connectors:

- 2 x Molex Microfit 3.0, 2 pin horizontal

Wire length:

- Heater 120mm

- Sensor 100mm

Revo HeaterCore: a super-compact heater and thermistor in one unit

Mounting and compatibility

We strongly believe in upgradability and backwards-compatibility where possible, but to make everything work together we’ve had to create some new interfaces for your 3D printer, within the ecosystem, and with our previous ecosystems.

With RapidChange Revo, the hot side is always the same: a HeaterCore and Revo Nozzle. It always interfaces with the cold side in the same way: with a Hemera-style HeatBreak. A variety of cold sides are available to enable you to upgrade or adapt your existing setup, or to design a printer around Revo.

Revo™ Six

Don’t worry E3D V6 owners – we have you covered!

Revo™ Six is a drop-in replacement for your E3D V6 HotEnd, meaning that any printer with a V6 setup should be able to use the very same mounting system with minimal fuss. Your Revo Six will ship with a premium crystal-clear duct, or if you prefer you can use your existing duct and fan without the need for design revisions.

Revo™ Six is a drop-in replacement for your E3D V6 HotEnd

Revo™ Micro

If you’re new to E3D products, our recommended mounting option is the Revo Micro. Besides the benefit of rapid nozzle swapping, the Revo Micro’s lightweight construction makes it ideal for squeezing extra motion system speed performance from your machine. A slick-looking anodised black aluminium heatsink is the smallest and lightest we’ve included on an E3D product so far.

The Revo Micro is is less than 30g in total, and is our recommended Revo HotEnd for compact, lightweight RapidChanging

The Revo Micro is suitable for Bowden and Direct Drive setups, and is compatible with all M12 mounting systems. A Nylon securing nut keeps the unit firmly in place and minimises extruder wobble during your print. Other mounting designs are coming down the line and will be announced very soon.

E3D's Revo HotEnds - three at launch, more to follow

Licensing

If you’ve been following our blog, you’ll have seen we recently announced a new strategy on IP. We’ve thought long and hard about what we protect, and our rationale for doing so. Here is what that means for RapidChange™ Revo™:

Open source is not dead at E3D

The RapidChange Revo cold side interface is open source, so you can design mounting systems to fit on whatever printer, wherever, whenever you like. In fact, we encourage you to design your own heatsinks and mounting systems as long as you use the Revo™ Nozzles and HeaterCores with it.

...But patents are also alive

The RapidChange Revo system itself is patent pending. As soon as the patent is published, or when the product is fully launched (whichever is sooner) we will share the detail on our E3D IP blog.

Sorry - but given the system that we're forced to operate within, it is not sensible for us to share more right now.

Pricing

At E3D, our raison d’etre is to change and improve the way humanity manufactures goods. That’s humanity, not humans-that-can-afford-the-luxury-of-spending-mega-bucks-on-projects. We strive to reflect this with our pricing, enabling as many as possible to adopt great extrusion systems without the premium price tag.

All the cool innovation you see in Revo is still going to cost you significantly less than anything else you’ll find in the market of this quality. In fact, for around £100 (that’s roughly 120 USD) you’ll not only get a full Revo HotEnd – you’ll have all four Revo nozzles to swap out.

Preorders

We plan to open for pre-orders around November 2021 and you'll be able to order directly from us or your favourite reseller. We expect Revo™ systems to start shipping around the end of the year.

Register your interest here and we’ll let you know as soon as pre-orders are live.

If you're a 3D printer manufacturer excited about integrating Revo into your printer, we'd be delighted to hear from you. Contact the sales team to share your requirements.

Find out more

FAQs:

Are you planning a 3mm variant?

Currently no – there is simply not enough demand to make it viable. However, if you are a large 3D printer manufacturer who really is attached to 3mm filament, we’re here to talk!

I have specific requirements that are not covered by the range available at launch. How can I find out when or if you’ll be meeting these requirements?

We have a solid roadmap of products to follow which will complement and complete the Revo system. You can contact the support team who will be able to help on any specific requirements. We’ll also share news on our blog and our social networks as new products come online.

We’re just as excited as you are about this new ecosystem of 3D printing products, and over the coming weeks we’ll be doing technical detail deep-dives into many of the features listed above. Don’t worry if there’s more you want to know: there's a lot more we have to say!

Be the first to know more